Page 23 - Adsorption Technology & Design, Elsevier (1998)

P. 23

20 Adsorbents

prevent oxidation of the carbon. Being a combustion process, tight controls

on environmental discharges are in place and the regeneration process is

prescribed for Integrated Pollution Control by the UK's Environment

Agency.

In powdered form activated carbon can be used directly, usually in batch

applications, but it cannot then be recovered easily for regeneration. Two

possibilities exist. First powdered activated carbon can be filtered off in

batch processing for subsequent regeneration. Alternatively, it can remain

in the sludge in water treament applications for subsequent disposal.

2.2 CARBON MOLECULAR SIEVES (CMS)

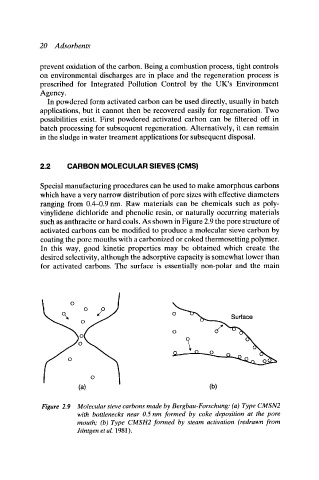

Special manufacturing procedures can be used to make amorphous carbons

which have a very narrow distribution of pore sizes with effective diameters

ranging from 0.4-0.9 nm. Raw materials can be chemicals such as poly-

vinylidene dichloride and phenolic resin, or naturally occurring materials

such as anthracite or hard coals. As shown in Figure 2.9 the pore structure of

activated carbons can be modified to produce a molecular sieve carbon by

coating the pore mouths with a carbonized or coked thermosetting polymer.

In this way, good kinetic properties may be obtained which create the

desired selectivity, although the adsorptive capacity is somewhat lower than

for activated carbons. The surface is essentially non-polar and the main

~

Surface

o o

o

(a) (b)

Figure 2.9 Molecular sieve carbons made by Bergbau-Forschung: (a) Type CMSN2

with bottlenecks near 0.5 nm formed by coke deposition at the pore

mouth; (b) Type CMSH2 formed by steam activation (redrawn from

JEintgen et al. 1981).