Page 31 - Adsorption Technology & Design, Elsevier (1998)

P. 31

28 Adsorbents

uptake of the adsorbates is suitable and that the appropriate purities can

be achieved. Again recourse may need to be given to experimentation if

the adsorbent vendor cannot supply the kinetic information. Further in-

formation on equilibria and kinetics is provided in Chapters 3 and 4,

respectively.

Given that the equilibria and kinetics of adsorption are appropriate,

consideration must next be given to the means by which the adsorbent is

going to be regenerated, if it is not to be discarded after use. Depending on

the process application, regeneration can be effected by changing the

pressure and/or the temperature or by some other physical or chemical

alteration to the system. Further information is provided in Chapter 5.

Consideration must also be given to factors such as the strength of the

adsorbent, its chemical resistance, its resistance to coking, etc., as well as to

its availability and price.

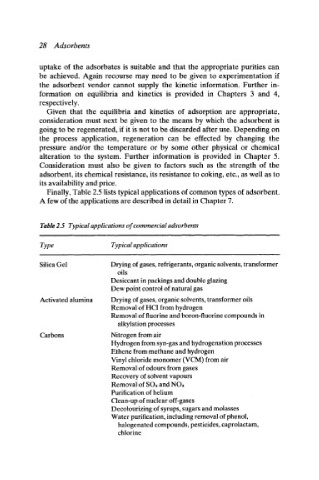

Finally, Table 2.5 lists typical applications of common types of adsorbent.

A few of the applications are described in detail in Chapter 7.

Table 2.5 Typical applications of commercial adsorbents

Type Typical applications

Drying of gases, refrigerants, organic solvents, transformer

Silica Gel

oils

Desiccant in packings and double glazing

Dew point control of natural gas

Activated alumina Drying of gases, organic solvents, transformer oils

Removal of HCI from hydrogen

Removal of fluorine and boron-fluorine compounds in

alkylation processes

Carbons Nitrogen from air

Hydrogen from syn-gas and hydrogenation processes

Ethene from methane and hydrogen

Vinyl chloride monomer (VCM) from air

Removal of odours from gases

Recovery of solvent vapours

Removal of SOx and NOx

Purification of helium

Clean-up of nuclear off-gases

Decolourizing of syrups, sugars and molasses

Water purification, including removal of phenol,

halogenated compounds, pesticides, caprolactam,

chlorine