Page 121 - Adsorption, Ion Exchange & Catalysis- 2007, Elsevier - Copy

P. 121

Else_AIEC-INGLE_cH003.qxd 7/13/2006 1:45 PM Page 117

3.4 Slurry Reactors 117

(a) (b) (c)

(d) (e)

utors:

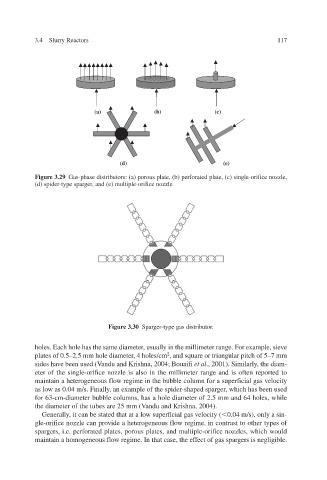

Figure 3.29 Gas-phase distrib (a) porous plate, (b) perforated plate, (c) single-orifice nozzle,

(d) spider-type spar, and (e) multiple-orifice nozzle ger

Figure 3.30 Sparger-type gas distributor.

holes. Each hole has the same diameter, usually in the millimeter range. For example, sieve

plates of 0.5–2.5 mm hole diameter, 4 holes/cm 2 , and square or triangular pitch of 5–7 mm

sides have been used (Vandu and Krishna, 2004; Bouaif i et al ., 2001). Similarly the diam- ,

eter of the single-orifice nozzle is also in the millimeter range and is often reported to

maintain a heterogeneous flow regime in the bubble column for a superficial gas v elocity

as low as 0.04 m/s. Finally, an example of the spider which has been used , ger -shaped spar

for 63-cm-diameter bubble columns, has a hole diameter of 2.5 mm and 64 holes, while

the diameter of the tubes are 25 mm (V 2004). andu and Krishna,

Generally, it can be stated that at a lo icial gas v w superf elocity ( 0.04 m/s), only a sin-

gle-orifice nozzle can provide a heterogeneous flow re in contrast to other types of

gime,

spargers, i.e. perforated plates, porous plates, and multiple-orifice nozzles, which w ould

maintain a homogeneous flow regime. In that case, the ef gligible. gers is ne fect of gas spar