Page 62 - Adsorption, Ion Exchange & Catalysis- 2007, Elsevier - Copy

P. 62

Else_AIEC-INGLE_cH003.qxd 7/13/2006 1:44 PM Page 58

58 3. Heterogeneous Processes and Reactor Analysis

where:

N the moles of reactant that appear in the reaction

t time

n the number of actie sites on the catalyst surf v ace.

This rate is usually referred to as the turnover frequency and it is the number of mole-

cules reacting per actie site per unit time at the conditions of the experiment (Boudart,

v

ilkinson,

,

ogler

1985; McNaught and W 1997; F 1999). Boudart (1995) used the term

“turnover frequenc to define the number of reolutions of the catalytic cycle per unit

v

y”

olution,

time and actie site. In each re one mole of reactant is consumed. For e xample,

v

v

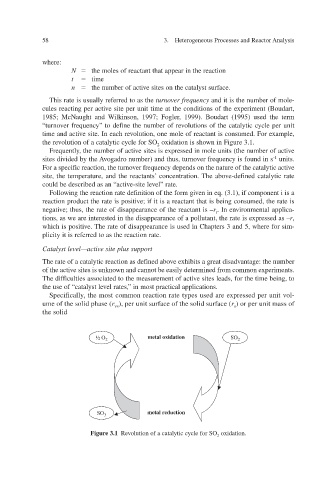

the revolution of a catalytic cycle for SO 2 oxidation is shown in Figure 3.1.

Frequently, the number of actie sites is expressed in mole units (the number of acti v v e

A

v sites divided by the ogadro number) and thus, turnoer frequency is found in s v -1 units.

y depends on the nature of the catalytic active For a specific reaction, the turno v er frequenc

site, the temperature, and the reactants’ concentration. The aboined catalytic rate v e-def

v el” e-site le could be described as an “acti rate. v

v

Following the reaction rate definition of the form gien in eq. (3.1), if component i is a

reaction product the rate is positie; if it is a reactant that is being consumed, the rate is

v

negative; thus, the rate of disappearance of the reactant is –r t . In environmental applica-

tions, as we are interested in the disappearance of a pollutant, the rate is expressed as –r ,

which is positiThe rate of disappearance is used in Chapters 3 and 5, where for sim-

e.

v

plicity it is referred to as the reaction rate.

Catalyst level—active site plus support

ined abo The rate of a catalytic reaction as defve exhibits a great disadvantage: the number

of the active sites is unknown and cannot be easily determined from common experiments.

f

The dificulties associated to the measurement of actie sites leads, for the time being, to

v

el rates, ” the use of “catalyst le in most practical applications. v

Specifically the most common reaction rate types used are expressed per unit vol-

,

ume of the solid phase ( r vs ), per unit surface of the solid surface ( r ) or per unit mass of

s

the solid

½ O 2 metal oxidation SO 2

SO 3 metal reduction

Figure 3.1 Revolution of a catalytic cycle for SO 2 oxidation.