Page 88 - Adsorption, Ion Exchange & Catalysis- 2007, Elsevier - Copy

P. 88

Else_AIEC-INGLE_cH003.qxd 7/13/2006 1:45 PM Page 84

84 3. Heterogeneous Processes and Reactor Analysis

unbaffled tank but a vortex creates problems, partial-length baffles may be used. These are

of standard width and extend downward from the surface into about one-third the liquid vol-

ume. In the region of laminar flow ( N Re < 10), the same po wer is consumed by the impeller

whether baffles are used or not, and the The flo y are not usually required. w pattern may be

.

When the

affected by the baf but not alays adv the baf antageously w y are needed, fles

fles,

are usually placed one or two widths radially off the tank w to allow fluid to circulate all,

behind them and at the same time produce some axial deflection of flow.

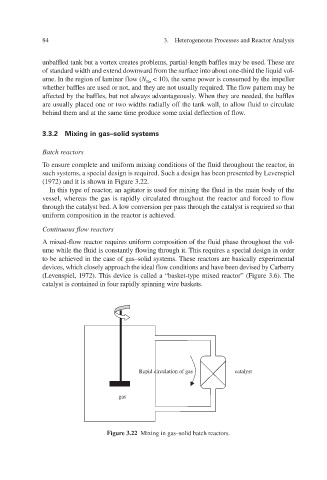

3.3.2 Mixing in gas–solid systems

Batch reactors

To ensure complete and uniform mixing conditions of the fluid throughout the reactor in ,

such systems, a special design is required. Such a design has been presented by Levenspiel

(1972) and it is shown in Figure 3.22.

,

In this type of reactor an agitator is used for mixing the fluid in the main body of the

vessel, whereas the gas is rapidly circulated throughout the reactor and forced to flo w

through the catalyst bed. A low conversion per pass through the catalyst is required so that

uniform composition in the reactor is achie ed. v

s eactor Continuous flow r

ol- ed-flow reactor requires uniform composition of the fluid phase throughout the v A mix

ume while the fluid is constantly flowing through it. This requires a special design in order

v to be achieed in the case of gas–solid systems. These reactors are basically e xperimental

devices, which closely approach the ideal flow conditions and have been devised by Carberry

(Levenspiel, 1972). This device is called a “basket-type mix (Figure 3.6). The ed reactor”

catalyst is contained in four rapidly spinning wire baskets.

Rapid circulon of gas i at catalys t

gas

Figure 3.22 Mixing in gas–solid batch reactors.