Page 152 - Advanced Gas Turbine Cycles

P. 152

Chapter 7. The combined cycle gas turbine (CCGT) 123

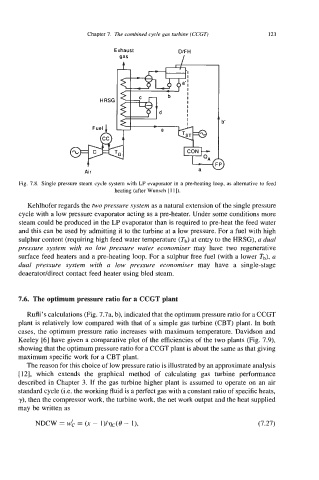

Exhaust DtFH

Fig. 7.8. Single pressure steam cycle system with LP evaporator in a pre-heating loop, as alternative to feed

heating (after Wunsch [I 11).

Kehlhofer regards the two pressure system as a natural extension of the single pressure

cycle with a low pressure evaporator acting as a pre-heater. Under some conditions more

steam could be produced in the LP evaporator than is required to pre-heat the feed water

and this can be used by admitting it to the turbine at a low pressure. For a fuel with high

sulphur content (requiring high feed water temperature (Tb) at entry to the HRSG), a dual

pressure system with no low pressure water economiser may have two regenerative

surface feed heaters and a pre-heating loop. For a sulphur free fuel (with a lower Tb), a

dual pressure system with a low pressure economiser may have a single-stage

deaeratoddirect contact feed heater using bled steam.

7.6. The optimum pressure ratio for a CCGT plant

Rufli’s calculations (Fig. 7.7a, b), indicated that the optimum pressure ratio for a CCGT

plant is relatively low compared with that of a simple gas turbine (CBT) plant. In both

cases, the optimum pressure ratio increases with maximum temperature. Davidson and

Keeley [6] have given a comparative plot of the efficiencies of the two plants (Fig. 7.9),

showing that the optimum pressure ratio for a CCGT plant is about the same as that giving

maximum specific work for a CBT plant.

The reason for this choice of low pressure ratio is illustrated by an approximate analysis

[ 121, which extends the graphical method of calculating gas turbine performance

described in Chapter 3. If the gas turbine higher plant is assumed to operate on an air

standard cycle (Le. the working fluid is a perfect gas with a constant ratio of specific heats,

y), then the compressor work, the turbine work, the net work output and the heat supplied

may be written as

mw w:: = (x - l)/q(-(O - I), (7.27)

=