Page 173 - Advanced Gas Turbine Cycles

P. 173

Chapter 8. Novel gas turbine cycles I39

from the last drum; carbon dioxide is collected from the other drums and compressed and

intercooled for final discharge.

Manfrida [4] argues that the heat demand and the substantial power loss associated with

‘presssure-swing’ physical absorption makes it less attractive than chemical absorption,

even for high pressure sequestration. The expansion work in the former is difficult to

recover as several expanders are needed.

8.4. Semi-closure

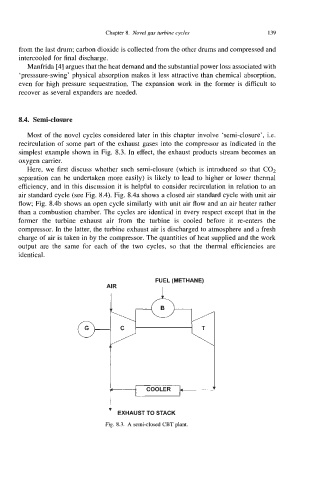

Most of the novel cycles considered later in this chapter involve ‘semi-closure’, Le.

recirculation of some part of the exhaust gases into the compressor as indicated in the

simplest example shown in Fig. 8.3. In effect, the exhaust products stream becomes an

oxygen carrier.

Here, we first discuss whether such semi-closure (which is introduced so that CO2

separation can be undertaken more easily) is likely to lead to higher or lower thermal

efficiency, and in this discussion it is helpful to consider recirculation in relation to an

air standard cycle (see Fig. 8.4). Fig. 8.4a shows a closed air standard cycle with unit air

flow; Fig. 8.4b shows an open cycle similarly with unit air flow and an air heater rather

than a combustion chamber. The cycles are identical in every respect except that in the

former the turbine exhaust air from the turbine is cooled before it re-enters the

compressor. In the latter, the turbine exhaust air is discharged to atmosphere and a fresh

charge of air is taken in by the compressor. The quantities of heat supplied and the work

output are the same for each of the two cycles, so that the thermal efficiencies are

identical.

FUEL (METHANE)

AIR I

1

COOLER

STACK

TO

EXHAUST

Fig. 8.3. A semi-closed CBT plant.