Page 174 - Advanced Gas Turbine Cycles

P. 174

Advanced gas turbine cycles

+ pjq

CLOSED T CYCLE

CYCLE

IL

COOLER v

A

3,

\ SEMI-CLOSED ’+

CYCLE T

COOLER 1r

+

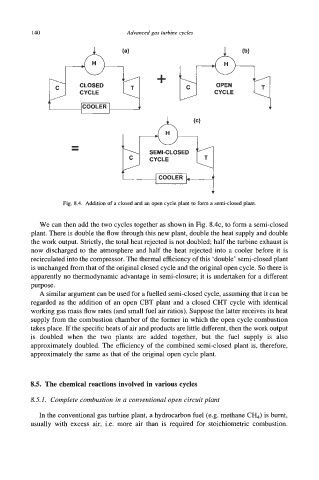

Fig. 8.4. Addition of a closed and an open cycle plant to form a semiclosed plant.

We can then add the two cycles together as shown in Fig. SAC, to form a semi-closed

plant. There is double the flow through this new plant, double the heat supply and double

the work output. Strictly, the total heat rejected is not doubled; half the turbine exhaust is

now discharged to the atmosphere and half the heat rejected into a cooler before it is

recirculated into the compressor. The thermal efficiency of this ‘double’ semi-closed plant

is unchanged from that of the original closed cycle and the original open cycle. So there is

apparently no thermodynamic advantage in semi-closure; it is undertaken for a different

purpose.

A similar argument can be used for a fuelled semi-closed cycle, assuming that it can be

regarded as the addition of an open CBT plant and a closed CHT cycle with identical

working gas mass flow rates (and small fuel air ratios). Suppose the latter receives its heat

supply from the combustion chamber of the former in which the open cycle combustion

takes place. If the specific heats of air and products are little different, then the work output

is doubled when the two plants are added together, but the fuel supply is also

approximately doubled. The efficiency of the combined semi-closed plant is, therefore,

approximately the same as that of the original open cycle plant.

8.5. The chemical reactions involved in various cycles

8.5.1. Complete combustion in a conventional open circuit plans

In the conventional gas turbine plant, a hydrocarbon fuel (e.g. methane CI&) is burnt,

usually with excess air, i.e. more air than is required for stoichiometric combustion.