Page 509 - Advanced thermodynamics for engineers

P. 509

502 CHAPTER 21 FUEL CELLS

Anode electrode

Matrix/electrode

assembly

Cathode

Internal electrode

manifold

Cathode

current collector

Separator

Lower cell plate

assemblies

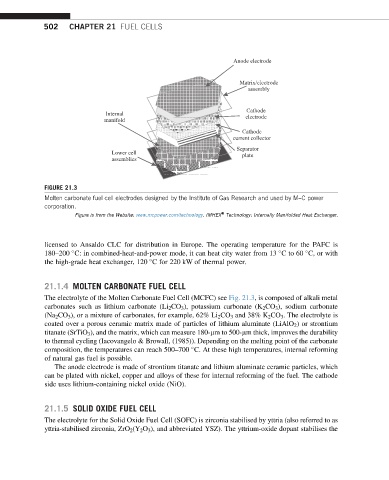

FIGURE 21.3

Molten carbonate fuel cell electrodes designed by the Institute of Gas Research and used by M–C power

corporation.

Ò

Figure is from the Website: www.mcpower.com/technology. IMHEX Technology: Internally Manifolded Heat Exchanger.

licensed to Ansaldo CLC for distribution in Europe. The operating temperature for the PAFC is

180–200 C: in combined-heat-and-power mode, it can heat city water from 13 Cto 60 C, or with

the high-grade heat exchanger, 120 C for 220 kW of thermal power.

21.1.4 MOLTEN CARBONATE FUEL CELL

The electrolyte of the Molten Carbonate Fuel Cell (MCFC) see Fig. 21.3, is composed of alkali metal

carbonates such as lithium carbonate (Li 2 CO 3 ), potassium carbonate (K 2 CO 3 ), sodium carbonate

(Na 2 CO 3 ), or a mixture of carbonates, for example, 62% Li 2 CO 3 and 38% K 2 CO 3 . The electrolyte is

coated over a porous ceramic matrix made of particles of lithium aluminate (LiAlO 2 ) or strontium

titanate (SrTiO 3 ), and the matrix, which can measure 180-mm to 500-mm thick, improves the durability

to thermal cycling (Iacovangelo & Browall, (1985)). Depending on the melting point of the carbonate

composition, the temperatures can reach 500–700 C. At these high temperatures, internal reforming

of natural gas fuel is possible.

The anode electrode is made of strontium titanate and lithium aluminate ceramic particles, which

can be plated with nickel, copper and alloys of these for internal reforming of the fuel. The cathode

side uses lithium-containing nickel oxide (NiO).

21.1.5 SOLID OXIDE FUEL CELL

The electrolyte for the Solid Oxide Fuel Cell (SOFC) is zirconia stabilised by yttria (also referred to as

yttria-stabilised zirconia, ZrO 2 (Y 2 O 3 ), and abbreviated YSZ). The yttrium-oxide dopant stabilises the