Page 135 - Advanced Mine Ventilation

P. 135

116 Advanced Mine Ventilation

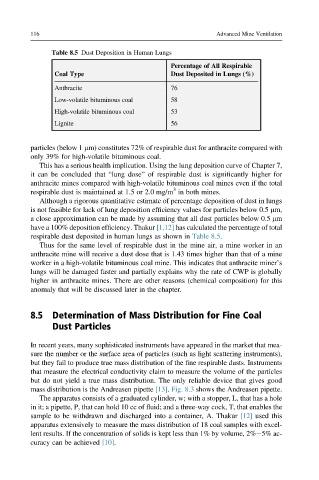

Table 8.5 Dust Deposition in Human Lungs

Percentage of All Respirable

Coal Type Dust Deposited in Lungs (%)

Anthracite 76

Low-volatile bituminous coal 58

High-volatile bituminous coal 53

Lignite 56

particles (below 1 mm) constitutes 72% of respirable dust for anthracite compared with

only 39% for high-volatile bituminous coal.

This has a serious health implication. Using the lung deposition curve of Chapter 7,

it can be concluded that “lung dose” of respirable dust is significantly higher for

anthracite mines compared with high-volatile bituminous coal mines even if the total

3

respirable dust is maintained at 1.5 or 2.0 mg/m in both mines.

Although a rigorous quantitative estimate of percentage deposition of dust in lungs

is not feasible for lack of lung deposition efficiency values for particles below 0.5 mm,

a close approximation can be made by assuming that all dust particles below 0.5 mm

have a 100% deposition efficiency. Thakur [1,12] has calculated the percentage of total

respirable dust deposited in human lungs as shown in Table 8.5.

Thus for the same level of respirable dust in the mine air, a mine worker in an

anthracite mine will receive a dust dose that is 1.43 times higher than that of a mine

worker in a high-volatile bituminous coal mine. This indicates that anthracite miner’s

lungs will be damaged faster and partially explains why the rate of CWP is globally

higher in anthracite mines. There are other reasons (chemical composition) for this

anomaly that will be discussed later in the chapter.

8.5 Determination of Mass Distribution for Fine Coal

Dust Particles

In recent years, many sophisticated instruments have appeared in the market that mea-

sure the number or the surface area of particles (such as light scattering instruments),

but they fail to produce true mass distribution of the fine respirable dusts. Instruments

that measure the electrical conductivity claim to measure the volume of the particles

but do not yield a true mass distribution. The only reliable device that gives good

mass distribution is the Andreasen pipette [13]. Fig. 8.3 shows the Andreasen pipette.

The apparatus consists of a graduated cylinder, w; with a stopper, L, that has a hole

in it; a pipette, P, that can hold 10 cc of fluid; and a three-way cock, T, that enables the

sample to be withdrawn and discharged into a container, A. Thakur [12] used this

apparatus extensively to measure the mass distribution of 18 coal samples with excel-

lent results. If the concentration of solids is kept less than 1% by volume, 2%e5% ac-

curacy can be achieved [10].