Page 146 - Advanced Mine Ventilation

P. 146

Generation of Respirable Coal Dust 127

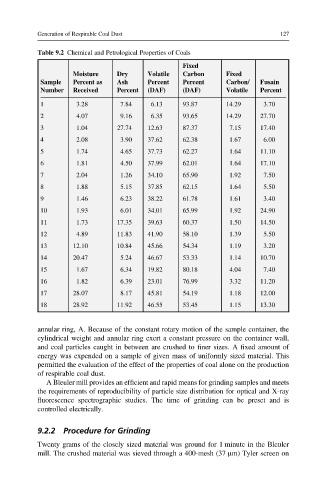

Table 9.2 Chemical and Petrological Properties of Coals

Fixed

Moisture Dry Volatile Carbon Fixed

Sample Percent as Ash Percent Percent Carbon/ Fusain

Number Received Percent (DAF) (DAF) Volatile Percent

1 3.28 7.84 6.13 93.87 14.29 3.70

2 4.07 9.16 6.35 93.65 14.29 27.70

3 1.04 27.74 12.63 87.37 7.15 17.40

4 2.08 3.90 37.62 62.38 1.67 6.00

5 1.74 4.65 37.73 62.27 1.64 11.10

6 1.81 4.50 37.99 62.01 1.64 17.10

7 2.04 1.26 34.10 65.90 1.92 7.50

8 1.88 5.15 37.85 62.15 1.64 5.50

9 1.46 6.23 38.22 61.78 1.61 3.40

10 1.93 6.01 34.01 65.99 1.92 24.90

11 1.73 17.35 39.63 60.37 1.50 14.50

12 4.89 11.83 41.90 58.10 1.39 5.50

13 12.10 10.84 45.66 54.34 1.19 3.20

14 20.47 5.24 46.67 53.33 1.14 10.70

15 1.67 6.34 19.82 80.18 4.04 7.40

16 1.82 6.39 23.01 76.99 3.32 11.20

17 28.07 8.17 45.81 54.19 1.18 12.00

18 28.92 11.92 46.55 53.45 1.15 13.30

annular ring, A. Because of the constant rotary motion of the sample container, the

cylindrical weight and annular ring exert a constant pressure on the container wall,

and coal particles caught in between are crushed to finer sizes. A fixed amount of

energy was expended on a sample of given mass of uniformly sized material. This

permitted the evaluation of the effect of the properties of coal alone on the production

of respirable coal dust.

A Bleuler mill provides an efficient and rapid means for grinding samples and meets

the requirements of reproducibility of particle size distribution for optical and X-ray

fluorescence spectrographic studies. The time of grinding can be preset and is

controlled electrically.

9.2.2 Procedure for Grinding

Twenty grams of the closely sized material was ground for 1 minute in the Bleuler

mill. The crushed material was sieved through a 400-mesh (37 mm) Tyler screen on