Page 145 - Advanced Mine Ventilation

P. 145

126 Advanced Mine Ventilation

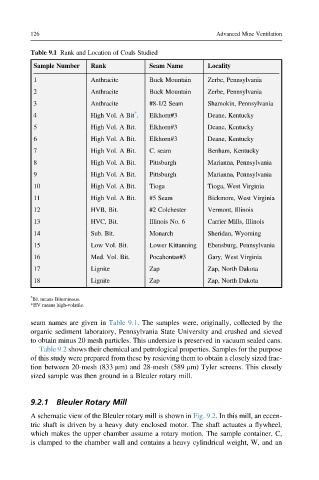

Table 9.1 Rank and Location of Coals Studied

Sample Number Rank Seam Name Locality

1 Anthracite Buck Mountain Zerbe, Pennsylvania

2 Anthracite Buck Mountain Zerbe, Pennsylvania

3 Anthracite #8-1/2 Seam Shamokin, Pennsylvania

*

4 High Vol. A Bit . Elkhorn#3 Deane, Kentucky

5 High Vol. A Bit. Elkhorn#3 Deane, Kentucky

6 High Vol. A Bit. Elkhorn#3 Deane, Kentucky

7 High Vol. A Bit. C. seam Benham, Kentucky

8 High Vol. A Bit. Pittsburgh Marianna, Pennsylvania

9 High Vol. A Bit. Pittsburgh Marianna, Pennsylvania

10 High Vol. A Bit. Tioga Tioga, West Virginia

11 High Vol. A Bit. #5 Seam Bickmore, West Virginia

12 HVB, Bit. #2 Colchester Vermont, Illinois

13 HVC, Bit. Illinois No. 6 Carrier Mills, Illinois

14 Sub. Bit. Monarch Sheridan, Wyoming

15 Low Vol. Bit. Lower Kittanning Ebensburg, Pennsylvania

16 Med. Vol. Bit. Pocahontas#3 Gary, West Virginia

17 Lignite Zap Zap, North Dakota

18 Lignite Zap Zap, North Dakota

*

Bit means Bituminous.

*HV means high-volatile.

seam names are given in Table 9.1. The samples were, originally, collected by the

organic sediment laboratory, Pennsylvania State University and crushed and sieved

to obtain minus 20 mesh particles. This undersize is preserved in vacuum sealed cans.

Table 9.2 shows their chemical and petrological properties. Samples for the purpose

of this study were prepared from these by resieving them to obtain a closely sized frac-

tion between 20-mesh (833 mm) and 28-mesh (589 mm) Tyler screens. This closely

sized sample was then ground in a Bleuler rotary mill.

9.2.1 Bleuler Rotary Mill

A schematic view of the Bleuler rotary mill is shown in Fig. 9.2. In this mill, an eccen-

tric shaft is driven by a heavy duty enclosed motor. The shaft actuates a flywheel,

which makes the upper chamber assume a rotary motion. The sample container, C,

is clamped to the chamber wall and contains a heavy cylindrical weight, W, and an