Page 257 - Advances In Productive, Safe, and Responsible Coal Mining

P. 257

236 Advances in Productive, Safe, and Responsible Coal Mining

Tail section

Cutting head

Tail roller

Foot shaft Conveyor path Dust scrubber fan

Fig. 12.19 Noise-generating components on a continuous mining machine.

12.4.3.1 Noise source identification

To identify dominant noise sources on a continuous mining machine, acoustic mea-

surements were conducted in a hemi-anechoic chamber at NIOSH. Noise-sensing

equipment included a 1.92-m-diameter, 42-element microphone phased array. The

CMM under test was a new JOY Model 14CM-15 continuous miner equipped with

a 956-mm-wide, 54-flight conveyor chain. NIOSH conducted beamforming testing

at the cutting drum and conveyor tail ends of the CMM. The length of the CMM

was several times the diameter of the microphone array necessitating a series of data

measurements along both sides of the CMM and then above the CMM to evaluate the

entire machine. Fig. 12.20 shows the CMM in the hemi-anechoic chamber with the

microphone phased array installed above the tail section.

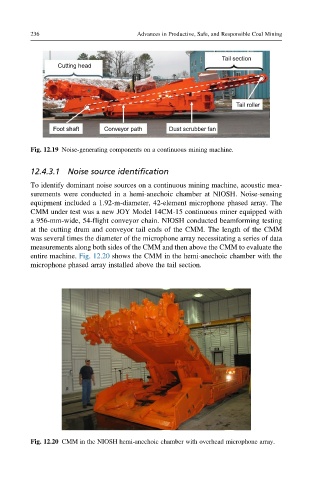

Fig. 12.20 CMM in the NIOSH hemi-anechoic chamber with overhead microphone array.