Page 252 - Advances In Productive, Safe, and Responsible Coal Mining

P. 252

Engineered noise controls for miner safety and environmental responsibility 231

110

100

99.2 dBA overall

90

L pA , dB(A) 80

70

60

100 125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300 8000 10,000 Overall

One-third octave band center frequency (Hz)

3

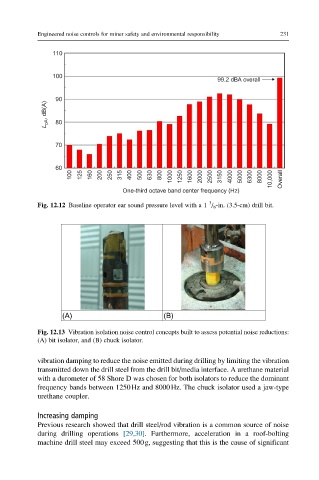

Fig. 12.12 Baseline operator ear sound pressure level with a 1 / 8 -in. (3.5-cm) drill bit.

(A) (B)

Fig. 12.13 Vibration isolation noise control concepts built to assess potential noise reductions:

(A) bit isolator, and (B) chuck isolator.

vibration damping to reduce the noise emitted during drilling by limiting the vibration

transmitted down the drill steel from the drill bit/media interface. A urethane material

with a durometer of 58 Shore D was chosen for both isolators to reduce the dominant

frequency bands between 1250Hz and 8000Hz. The chuck isolator used a jaw-type

urethane coupler.

Increasing damping

Previous research showed that drill steel/rod vibration is a common source of noise

during drilling operations [29,30]. Furthermore, acceleration in a roof-bolting

machine drill steel may exceed 500g, suggesting that this is the cause of significant