Page 132 - Advances in bioenergy (2016)

P. 132

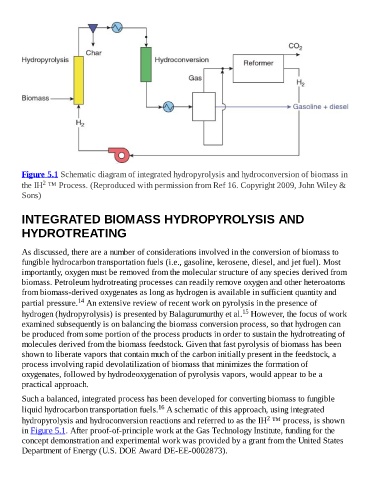

Figure 5.1 Schematic diagram of integrated hydropyrolysis and hydroconversion of biomass in

2

the IH ™ Process. (Reproduced with permission from Ref 16. Copyright 2009, John Wiley &

Sons)

INTEGRATED BIOMASS HYDROPYROLYSIS AND

HYDROTREATING

As discussed, there are a number of considerations involved in the conversion of biomass to

fungible hydrocarbon transportation fuels (i.e., gasoline, kerosene, diesel, and jet fuel). Most

importantly, oxygen must be removed from the molecular structure of any species derived from

biomass. Petroleum hydrotreating processes can readily remove oxygen and other heteroatoms

from biomass-derived oxygenates as long as hydrogen is available in sufficient quantity and

14

partial pressure. An extensive review of recent work on pyrolysis in the presence of

15

hydrogen (hydropyrolysis) is presented by Balagurumurthy et al. However, the focus of work

examined subsequently is on balancing the biomass conversion process, so that hydrogen can

be produced from some portion of the process products in order to sustain the hydrotreating of

molecules derived from the biomass feedstock. Given that fast pyrolysis of biomass has been

shown to liberate vapors that contain much of the carbon initially present in the feedstock, a

process involving rapid devolatilization of biomass that minimizes the formation of

oxygenates, followed by hydrodeoxygenation of pyrolysis vapors, would appear to be a

practical approach.

Such a balanced, integrated process has been developed for converting biomass to fungible

16

liquid hydrocarbon transportation fuels. A schematic of this approach, using integrated

2

hydropyrolysis and hydroconversion reactions and referred to as the IH ™ process, is shown

in Figure 5.1. After proof-of-principle work at the Gas Technology Institute, funding for the

concept demonstration and experimental work was provided by a grant from the United States

Department of Energy (U.S. DOE Award DE-EE-0002873).