Page 136 - Advances in bioenergy (2016)

P. 136

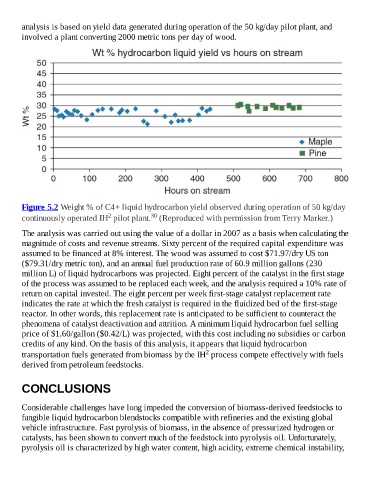

analysis is based on yield data generated during operation of the 50 kg/day pilot plant, and

involved a plant converting 2000 metric tons per day of wood.

Figure 5.2 Weight % of C4+ liquid hydrocarbon yield observed during operation of 50 kg/day

2

30

continuously operated IH pilot plant. (Reproduced with permission from Terry Marker.)

The analysis was carried out using the value of a dollar in 2007 as a basis when calculating the

magnitude of costs and revenue streams. Sixty percent of the required capital expenditure was

assumed to be financed at 8% interest. The wood was assumed to cost $71.97/dry US ton

($79.31/dry metric ton), and an annual fuel production rate of 60.9 million gallons (230

million L) of liquid hydrocarbons was projected. Eight percent of the catalyst in the first stage

of the process was assumed to be replaced each week, and the analysis required a 10% rate of

return on capital invested. The eight percent per week first-stage catalyst replacement rate

indicates the rate at which the fresh catalyst is required in the fluidized bed of the first-stage

reactor. In other words, this replacement rate is anticipated to be sufficient to counteract the

phenomena of catalyst deactivation and attrition. A minimum liquid hydrocarbon fuel selling

price of $1.60/gallon ($0.42/L) was projected, with this cost including no subsidies or carbon

credits of any kind. On the basis of this analysis, it appears that liquid hydrocarbon

2

transportation fuels generated from biomass by the IH process compete effectively with fuels

derived from petroleum feedstocks.

CONCLUSIONS

Considerable challenges have long impeded the conversion of biomass-derived feedstocks to

fungible liquid hydrocarbon blendstocks compatible with refineries and the existing global

vehicle infrastructure. Fast pyrolysis of biomass, in the absence of pressurized hydrogen or

catalysts, has been shown to convert much of the feedstock into pyrolysis oil. Unfortunately,

pyrolysis oil is characterized by high water content, high acidity, extreme chemical instability,