Page 156 - Advances in bioenergy (2016)

P. 156

as gasification agent.

The great advantage of the autothermal gasification is the direct heating of the reactants and

therefore more efficient energy utilization. The process is simpler than by allothermal

gasification and it is easier to operate it under pressurized conditions.

Allothermal (or indirect) gasification is characterized by the separation of the processes of

4

heat production and heat consumption. The allothermal gasification facility almost always

consists of two reactors, connected by an energy flow. Biomass is gasified in the first reactor

and the remaining solid residue (char) or product gas is combusted in the second reactor to

produce the heat for the first process. The transport of the heat can be done either by

circulating a bed material or by heat exchangers.

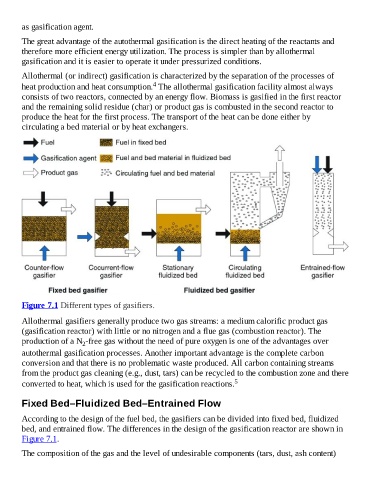

Figure 7.1 Different types of gasifiers.

Allothermal gasifiers generally produce two gas streams: a medium calorific product gas

(gasification reactor) with little or no nitrogen and a flue gas (combustion reactor). The

production of a N -free gas without the need of pure oxygen is one of the advantages over

2

autothermal gasification processes. Another important advantage is the complete carbon

conversion and that there is no problematic waste produced. All carbon containing streams

from the product gas cleaning (e.g., dust, tars) can be recycled to the combustion zone and there

converted to heat, which is used for the gasification reactions. 5

Fixed Bed–Fluidized Bed–Entrained Flow

According to the design of the fuel bed, the gasifiers can be divided into fixed bed, fluidized

bed, and entrained flow. The differences in the design of the gasification reactor are shown in

Figure 7.1.

The composition of the gas and the level of undesirable components (tars, dust, ash content)