Page 157 - Advances in bioenergy (2016)

P. 157

produced during biomass gasification process are dependent on many factors such as feedstock

composition, reactor type, and operating parameters (temperature, pressure, oxygen fuel ratio).

Oxygen Blown–Steam Blown

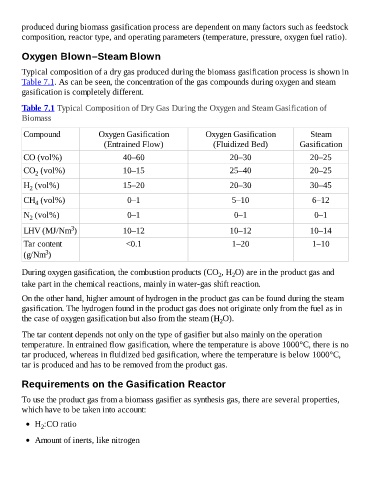

Typical composition of a dry gas produced during the biomass gasification process is shown in

Table 7.1. As can be seen, the concentration of the gas compounds during oxygen and steam

gasification is completely different.

Table 7.1 Typical Composition of Dry Gas During the Oxygen and Steam Gasification of

Biomass

Compound Oxygen Gasification Oxygen Gasification Steam

(Entrained Flow) (Fluidized Bed) Gasification

CO (vol%) 40–60 20–30 20–25

CO (vol%) 10–15 25–40 20–25

2

H (vol%) 15–20 20–30 30–45

2

CH (vol%) 0–1 5–10 6–12

4

N (vol%) 0–1 0–1 0–1

2

3

LHV (MJ/Nm ) 10–12 10–12 10–14

Tar content <0.1 1–20 1–10

3

(g/Nm )

During oxygen gasification, the combustion products (CO , H O) are in the product gas and

2

2

take part in the chemical reactions, mainly in water-gas shift reaction.

On the other hand, higher amount of hydrogen in the product gas can be found during the steam

gasification. The hydrogen found in the product gas does not originate only from the fuel as in

the case of oxygen gasification but also from the steam (H O).

2

The tar content depends not only on the type of gasifier but also mainly on the operation

temperature. In entrained flow gasification, where the temperature is above 1000°C, there is no

tar produced, whereas in fluidized bed gasification, where the temperature is below 1000°C,

tar is produced and has to be removed from the product gas.

Requirements on the Gasification Reactor

To use the product gas from a biomass gasifier as synthesis gas, there are several properties,

which have to be taken into account:

H :CO ratio

2

Amount of inerts, like nitrogen