Page 168 - Advances in bioenergy (2016)

P. 168

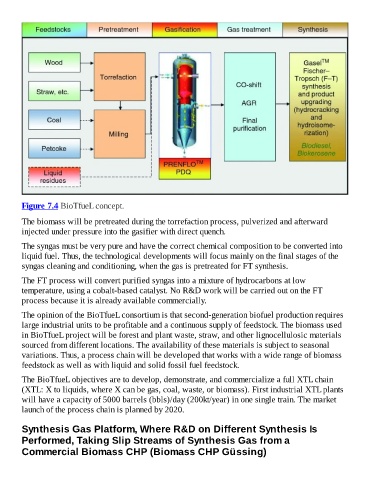

Figure 7.4 BioTfueL concept.

The biomass will be pretreated during the torrefaction process, pulverized and afterward

injected under pressure into the gasifier with direct quench.

The syngas must be very pure and have the correct chemical composition to be converted into

liquid fuel. Thus, the technological developments will focus mainly on the final stages of the

syngas cleaning and conditioning, when the gas is pretreated for FT synthesis.

The FT process will convert purified syngas into a mixture of hydrocarbons at low

temperature, using a cobalt-based catalyst. No R&D work will be carried out on the FT

process because it is already available commercially.

The opinion of the BioTfueL consortium is that second-generation biofuel production requires

large industrial units to be profitable and a continuous supply of feedstock. The biomass used

in BioTfueL project will be forest and plant waste, straw, and other lignocellulosic materials

sourced from different locations. The availability of these materials is subject to seasonal

variations. Thus, a process chain will be developed that works with a wide range of biomass

feedstock as well as with liquid and solid fossil fuel feedstock.

The BioTfueL objectives are to develop, demonstrate, and commercialize a full XTL chain

(XTL: X to liquids, where X can be gas, coal, waste, or biomass). First industrial XTL plants

will have a capacity of 5000 barrels (bbls)/day (200kt/year) in one single train. The market

launch of the process chain is planned by 2020.

Synthesis Gas Platform, Where R&D on Different Synthesis Is

Performed, Taking Slip Streams of Synthesis Gas from a

Commercial Biomass CHP (Biomass CHP Güssing)