Page 169 - Advances in bioenergy (2016)

P. 169

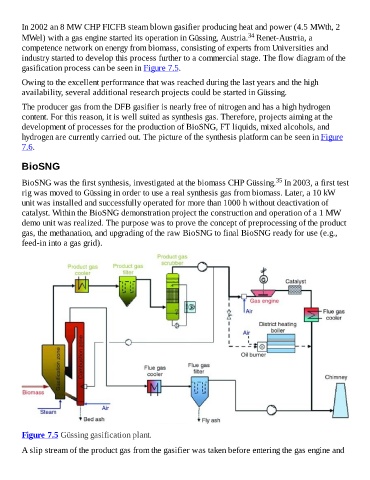

In 2002 an 8 MW CHP FICFB steam blown gasifier producing heat and power (4.5 MWth, 2

34

MWel) with a gas engine started its operation in Güssing, Austria. Renet-Austria, a

competence network on energy from biomass, consisting of experts from Universities and

industry started to develop this process further to a commercial stage. The flow diagram of the

gasification process can be seen in Figure 7.5.

Owing to the excellent performance that was reached during the last years and the high

availability, several additional research projects could be started in Güssing.

The producer gas from the DFB gasifier is nearly free of nitrogen and has a high hydrogen

content. For this reason, it is well suited as synthesis gas. Therefore, projects aiming at the

development of processes for the production of BioSNG, FT liquids, mixed alcohols, and

hydrogen are currently carried out. The picture of the synthesis platform can be seen in Figure

7.6.

BioSNG

35

BioSNG was the first synthesis, investigated at the biomass CHP Güssing. In 2003, a first test

rig was moved to Güssing in order to use a real synthesis gas from biomass. Later, a 10 kW

unit was installed and successfully operated for more than 1000 h without deactivation of

catalyst. Within the BioSNG demonstration project the construction and operation of a 1 MW

demo unit was realized. The purpose was to prove the concept of preprocessing of the product

gas, the methanation, and upgrading of the raw BioSNG to final BioSNG ready for use (e.g.,

feed-in into a gas grid).

Figure 7.5 Güssing gasification plant.

A slip stream of the product gas from the gasifier was taken before entering the gas engine and