Page 203 - Advances in bioenergy (2016)

P. 203

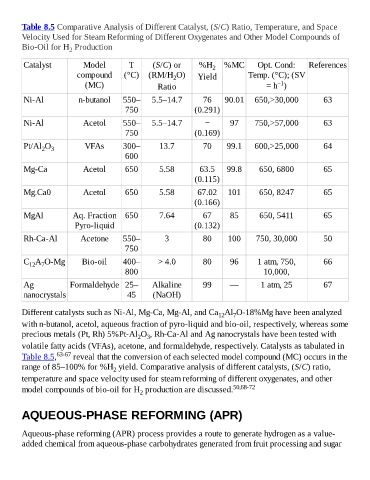

Table 8.5 Comparative Analysis of Different Catalyst, (S/C) Ratio, Temperature, and Space

Velocity Used for Steam Reforming of Different Oxygenates and Other Model Compounds of

Bio-Oil for H Production

2

Catalyst Model T (S/C) or %H 2 %MC Opt. Cond: References

compound (°C) (RM/H O) Yield Temp. (°C); (SV

2

−1

(MC) Ratio = h )

Ni-Al n-butanol 550– 5.5–14.7 76 90.01 650,>30,000 63

750 (0.291)

Ni-Al Acetol 550– 5.5–14.7 − 97 750,>57,000 63

750 (0.169)

Pt/Al O VFAs 300– 13.7 70 99.1 600,>25,000 64

2 3

600

Mg-Ca Acetol 650 5.58 63.5 99.8 650, 6800 65

(0.115)

Mg.Ca0 Acetol 650 5.58 67.02 101 650, 8247 65

(0.166)

MgAl Aq. Fraction 650 7.64 67 85 650, 5411 65

Pyro-liquid (0.132)

Rh-Ca-Al Acetone 550– 3 80 100 750, 30,000 50

750

C A O-Mg Bio-oil 400– > 4.0 80 96 1 atm, 750, 66

12 7

800 10,000,

Ag Formaldehyde 25– Alkaline 99 — 1 atm, 25 67

nanocrystals 45 (NaOH)

Different catalysts such as Ni-Al, Mg-Ca, Mg-Al, and Ca Al O-18%Mg have been analyzed

12

7

with n-butanol, acetol, aqueous fraction of pyro-liquid and bio-oil, respectively, whereas some

precious metals (Pt, Rh) 5%Pt-Al O , Rh-Ca-Al and Ag nanocrystals have been tested with

2 3

volatile fatty acids (VFAs), acetone, and formaldehyde, respectively. Catalysts as tabulated in

Table 8.5, 63-67 reveal that the conversion of each selected model compound (MC) occurs in the

range of 85–100% for %H yield. Comparative analysis of different catalysts, (S/C) ratio,

2

temperature and space velocity used for steam reforming of different oxygenates, and other

model compounds of bio-oil for H production are discussed. 50,68-72

2

AQUEOUS-PHASE REFORMING (APR)

Aqueous-phase reforming (APR) process provides a route to generate hydrogen as a value-

added chemical from aqueous-phase carbohydrates generated from fruit processing and sugar