Page 254 - Advances in Eco-Fuels for a Sustainable Environment

P. 254

Prospects and technological advancement of cellulosic bioethanol ecofuel production 217

as electrochemical synthesis, oxide electrolysis, and petroleum hydroprocessing is ter-

med fourth-generation bioethanol [34, 35]. In the environmental context, fourth-

generation bioethanol is considered carbon negative as carbon produced from this

technology is less compared to the carbon captured. However, this technology is in

its embryonic stage.

8.4 Progress in bioethanol technologies

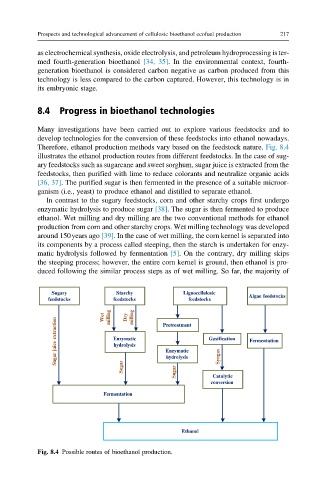

Many investigations have been carried out to explore various feedstocks and to

develop technologies for the conversion of these feedstocks into ethanol nowadays.

Therefore, ethanol production methods vary based on the feedstock nature. Fig. 8.4

illustrates the ethanol production routes from different feedstocks. In the case of sug-

ary feedstocks such as sugarcane and sweet sorghum, sugar juice is extracted from the

feedstocks, then purified with lime to reduce colorants and neutralize organic acids

[36, 37]. The purified sugar is then fermented in the presence of a suitable microor-

ganism (i.e., yeast) to produce ethanol and distilled to separate ethanol.

In contrast to the sugary feedstocks, corn and other starchy crops first undergo

enzymatic hydrolysis to produce sugar [38]. The sugar is then fermented to produce

ethanol. Wet milling and dry milling are the two conventional methods for ethanol

production from corn and other starchy crops. Wet milling technology was developed

around 150years ago [39]. In the case of wet milling, the corn kernel is separated into

its components by a process called steeping, then the starch is undertaken for enzy-

matic hydrolysis followed by fermentation [5]. On the contrary, dry milling skips

the steeping process; however, the entire corn kernel is ground, then ethanol is pro-

duced following the similar process steps as of wet milling. So far, the majority of

Sugary Starchy Lignocellulosic

feedstocks Wet milling feedstocks milling feedstocks Algae feedstocks

Dry

Sugar juice extraction Enzymatic Pretreatment Gasification Fermentation

hydrolysis

Enzymatic

Sugar hydrolysis Syngas

Sugar

Catalytic

conversion

Fermentation

Ethanol

Fig. 8.4 Possible routes of bioethanol production.