Page 289 - Advances in Eco-Fuels for a Sustainable Environment

P. 289

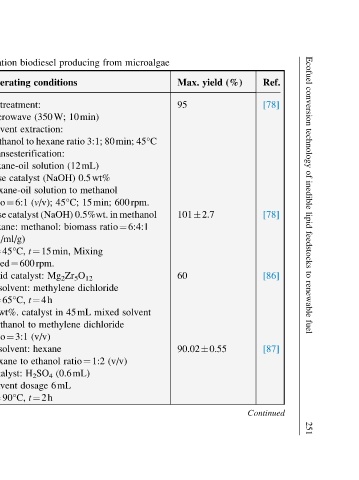

Ecofuel conversion technology of inedible lipid feedstocks to renewable fuel 251

Continued

Ref. [78] [78] [86] [87]

(%)

yield 90.02 0.55

Max. 95 101 2.7 60

microalgae 600rpm. solvent

from methanol 15min; ratio¼6:4:1 dichloride mixed dichloride (v/v)

producing 10min) methanol to hexane ratio 3:1; 80min; 45°C (12mL) 0.5wt% (NaOH) to 45°C; Base catalyst (NaOH) 0.5%wt. in methanol biomass Mixing Mg 2 Zr 5 O 12 45mL methylene ratio¼1:2 (0.6mL) 6mL

biodiesel conditions Pretreatment: (350W; extraction: Transesterification: solution catalyst solution (v/v); methanol: t¼15min, speed¼600rpm. catalyst: methylene t¼4h in catalyst to (v/v) hexane ethanol to H 2 SO 4 dosage t¼2h

transesterification Operating microwave Solvent hexane-oil Base Hexane-oil ratio¼6:1 hexane: (ml/ml/g) T¼45°C, Solid Cosolvent: T¼65°C, 10wt%. Methanol ratio¼3:1 Cosolvent: Hexane Catalyst: Solvent T¼90°C,

two-step JSC4 biomass) JSC4 56.6%–60.5%)

and strains sp. dry sp. content:

trans(esterification) Microalgae Chlamydo-monas 31.3% (slurry: Chlamydomonas solid (Cake, Nannochloropsis sp. Chlorella

situ

in

Catalytic

9.6 transesterification trans(esterification) trans(esterification) trans(esterification)

Table Process Two-step situ In situ In situ In