Page 290 - Advances in Eco-Fuels for a Sustainable Environment

P. 290

252

[81]

Ref.

[81]

[77]

(%)

yield

Max.

94.6

99.7

42

speed¼500rpm.

(20wt%)

(ml/g)

pumice

2mL

biomass¼12:1

Mixing

50μL

H 2 SO 4 :50μL

chloroform:

conditions

impregnated

200mg

200mg

t¼1h

t¼1h

t¼3h,

H 2 SO 4:

t¼2h

2mL

1mL

biomass:

biomass:

to

Operating

T¼100°C,

T¼100°C,

Cosolvent

Methanol:

T¼80°C,

T¼95°C,

Methanol

Catalyst:

Ethanol:

Catalyst

Catalyst

Wet

Wet

(moisture

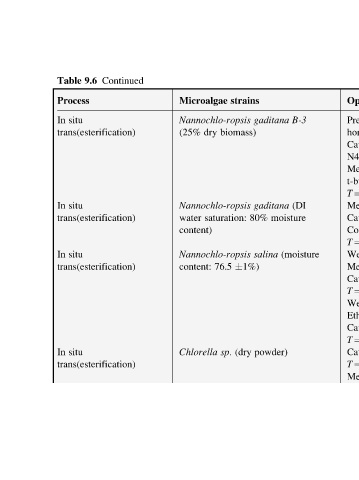

B-3 [85] 99.5 pressure high Pre-treatment: homogenization (N435) 435 Novozym Catalyst: ratio¼0.32:1 mass oil to N435 (ml/g) 1 ratio¼4.6: oil to Methanol (ml/g) ratio¼7.1:1 oil to t-butanol t¼56h T¼40°C, [84] 85.7 1.7 1mL Methanol: (DI 0.3mL HCl: Catalyst moisture Advances in Eco-Fuels for a Su

gaditana gaditana 80% salina powder)

strains biomass) saturation: 1%) (dry sp.

Microalgae Nannochlo-ropsis dry (25% Nannochlo-ropsis water content) Nannochlo-ropsis 76.5 content: Chlorella

Continued

9.6 trans(esterification) trans(esterification) trans(esterification) trans(esterification)

Table Process situ In situ In situ In situ In