Page 296 - Advances in Eco-Fuels for a Sustainable Environment

P. 296

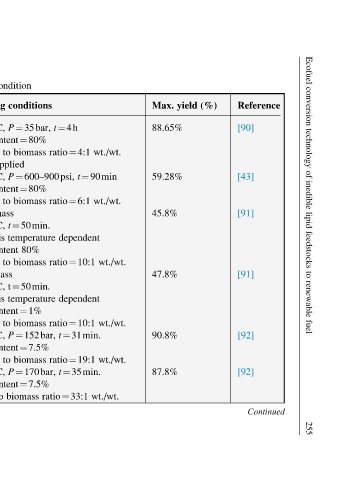

Ecofuel conversion technology of inedible lipid feedstocks to renewable fuel 255

Reference [90] [43] [91] [91] [92] [92] Continued

(%)

yield

Max. 88.65% 59.28% 45.8% 47.8% 90.8% 87.8%

wt./wt. t¼90min wt./wt. wt./wt. wt./wt. wt./wt. wt./wt.

t¼4h ratio¼4:1 P¼600–900psi, ratio¼6:1 dependent ratio¼10:1 dependent ratio¼10:1 t¼31min. ratio¼19:1 t¼35min. ratio¼33:1

condition conditions P¼35bar, content¼80% biomass to applied content¼80% biomass to biomass t¼50min. temperature is 80% content biomass to biomass t¼50min. temperature is content¼1% biomass to P¼152bar, content¼7.5% biomass to P¼170bar, content¼7.5% biomass to

sub/supercritical Operating T¼175°C, Water Methanol Stirring T¼225°C, Water Methanol Wet T¼265°C, Pressure Water Methanol Dry T¼255°C, Pressure Water Methanol T¼320°C, Water Methanol T¼340°C, Water Ethanol

under strains vulgaris dry)

microalgae Microalgae Chlorella (wet) Nannochloropsis gaditana (wet) Nannochloropsis gaditana and (wet Chlorella protothecoides

from

production

Biodiesel situ in (two-step

9.7 trans(esterification) Supercritical Supercritical transesterification)

Table Process Subcritical