Page 307 - Advances in Eco-Fuels for a Sustainable Environment

P. 307

264 Advances in Eco-Fuels for a Sustainable Environment

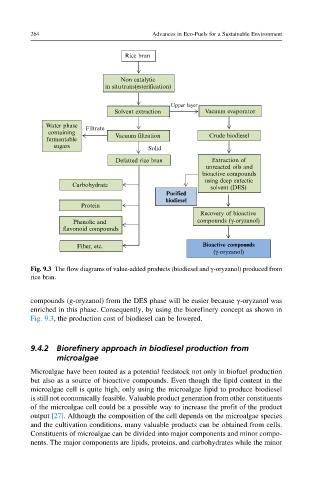

Rice bran

Non catalytic

in situ trans(esterification)

Upper layer

Solvent extraction Vacuum evaporator

Water phase Filtrate

containing

fermentable Vacuum filtration Crude biodiesel

sugars Solid

Defatted rice bran Extraction of

unreacted oils and

bioactive compounds

using deep eutectic

Carbohydrate

solvent (DES)

Purified

biodiesel

Protein

Recovery of bioactive

Phenolic and compounds (γ-oryzanol)

flavonoid compounds

Fiber, etc. Bioactive compounds

(γ-oryzanol)

Fig. 9.3 The flow diagrams of value-added products (biodiesel and γ-oryzanol) produced from

rice bran.

compounds (g-oryzanol) from the DES phase will be easier because γ-oryzanol was

enriched in this phase. Consequently, by using the biorefinery concept as shown in

Fig. 9.3, the production cost of biodiesel can be lowered.

9.4.2 Biorefinery approach in biodiesel production from

microalgae

Microalgae have been touted as a potential feedstock not only in biofuel production

but also as a source of bioactive compounds. Even though the lipid content in the

microalgae cell is quite high, only using the microalgae lipid to produce biodiesel

is still not economically feasible. Valuable product generation from other constituents

of the microalgae cell could be a possible way to increase the profit of the product

output [27]. Although the composition of the cell depends on the microalgae species

and the cultivation conditions, many valuable products can be obtained from cells.

Constituents of microalgae can be divided into major components and minor compo-

nents. The major components are lipids, proteins, and carbohydrates while the minor