Page 303 - Advances in Eco-Fuels for a Sustainable Environment

P. 303

260 Advances in Eco-Fuels for a Sustainable Environment

OH

OH

O

Kahweol

N

O N

O N N

OH

OH Caffeine

Cafestol

O

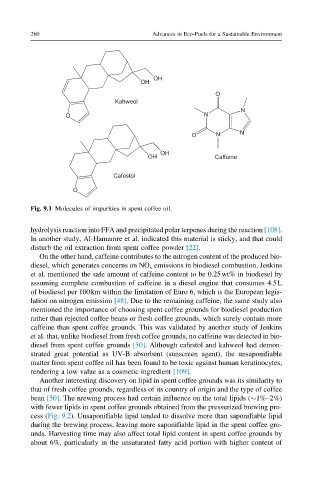

Fig. 9.1 Molecules of impurities in spent coffee oil.

hydrolysis reaction into FFA and precipitated polar terpenes during the reaction [108].

In another study, Al-Hamamre et al. indicated this material is sticky, and that could

disturb the oil extraction from spent coffee powder [22].

On the other hand, caffeine contributes to the nitrogen content of the produced bio-

diesel, which generates concerns on NO x emissions in biodiesel combustion. Jenkins

et al. mentioned the safe amount of caffeine content to be 0.25wt% in biodiesel by

assuming complete combustion of caffeine in a diesel engine that consumes 4.5L

of biodiesel per 100km within the limitation of Euro 6, which is the European legis-

lation on nitrogen emission [48]. Due to the remaining caffeine, the same study also

mentioned the importance of choosing spent coffee grounds for biodiesel production

rather than rejected coffee beans or fresh coffee grounds, which surely contain more

caffeine than spent coffee grounds. This was validated by another study of Jenkins

et al. that, unlike biodiesel from fresh coffee grounds, no caffeine was detected in bio-

diesel from spent coffee grounds [50]. Although cafestol and kahweol had demon-

strated great potential as UV-B absorbent (sunscreen agent), the unsaponifiable

matter from spent coffee oil has been found to be toxic against human keratinocytes,

rendering a low value as a cosmetic ingredient [109].

Another interesting discovery on lipid in spent coffee grounds was its similarity to

that of fresh coffee grounds, regardless of its country of origin and the type of coffee

bean [50]. The nrewing process had certain influence on the total lipids ( 1%–2%)

with fewer lipids in spent coffee grounds obtained from the pressurized brewing pro-

cess (Fig. 9.2). Unsaponifiable lipid tended to dissolve more than saponifiable lipid

during the brewing process, leaving more saponifiable lipid in the spent coffee gro-

unds. Harvesting time may also affect total lipid content in spent coffee grounds by

about 6%, particularly in the unsaturated fatty acid portion with higher content of