Page 346 - Advances in Eco-Fuels for a Sustainable Environment

P. 346

Thermal depolymerization of biogas digestate 301

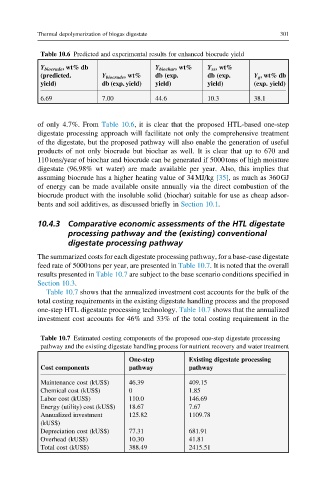

Table 10.6 Predicted and experimental results for enhanced biocrude yield

Y biocrude , wt% db Y biochar , wt% Y ss , wt%

(predicted. Y biocrude , wt% db (exp. db (exp. Y g , wt% db

yield) db (exp. yield) yield) yield) (exp. yield)

6.69 7.00 44.6 10.3 38.1

of only 4.7%. From Table 10.6, it is clear that the proposed HTL-based one-step

digestate processing approach will facilitate not only the comprehensive treatment

of the digestate, but the proposed pathway will also enable the generation of useful

products of not only biocrude but biochar as well. It is clear that up to 670 and

110tons/year of biochar and biocrude can be generated if 5000tons of high moisture

digestate (96.98% wt water) are made available per year. Also, this implies that

assuming biocrude has a higher heating value of 34MJ/kg [35], as much as 360GJ

of energy can be made available onsite annually via the direct combustion of the

biocrude product with the insoluble solid (biochar) suitable for use as cheap adsor-

bents and soil additives, as discussed briefly in Section 10.1.

10.4.3 Comparative economic assessments of the HTL digestate

processing pathway and the (existing) conventional

digestate processing pathway

The summarized costs for each digestate processing pathway, for a base-case digestate

feed rate of 5000tons per year, are presented in Table 10.7. It is noted that the overall

results presented in Table 10.7 are subject to the base scenario conditions specified in

Section 10.3.

Table 10.7 shows that the annualized investment cost accounts for the bulk of the

total costing requirements in the existing digestate handling process and the proposed

one-step HTL digestate processing technology. Table 10.7 shows that the annualized

investment cost accounts for 46% and 33% of the total costing requirement in the

Table 10.7 Estimated costing components of the proposed one-step digestate processing

pathway and the existing digestate handling process for nutrient recovery and water treatment

One-step Existing digestate processing

Cost components pathway pathway

Maintenance cost (kUS$) 46.39 409.15

Chemical cost (kUS$) 0 1.85

Labor cost (kUS$) 110.0 146.69

Energy (utility) cost (kUS$) 18.67 7.67

Annualized investment 125.82 1109.78

(kUS$)

Depreciation cost (kUS$) 77.31 681.91

Overhead (kUS$) 10.30 41.81

Total cost (kUS$) 388.49 2415.51