Page 362 - Advances in Eco-Fuels for a Sustainable Environment

P. 362

Physicochemical fuel properties and tribological behavior of aegle marmelos correa biodiesel 317

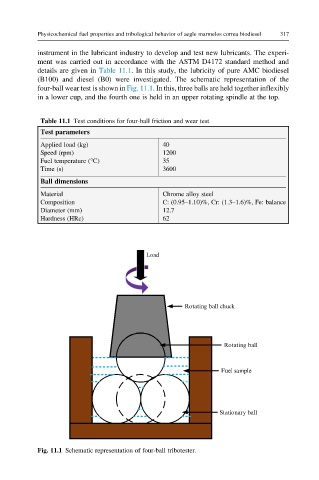

instrument in the lubricant industry to develop and test new lubricants. The experi-

ment was carried out in accordance with the ASTM D4172 standard method and

details are given in Table 11.1. In this study, the lubricity of pure AMC biodiesel

(B100) and diesel (B0) were investigated. The schematic representation of the

four-ball wear test is shown in Fig. 11.1. In this, three balls are held together inflexibly

in a lower cup, and the fourth one is held in an upper rotating spindle at the top.

Table 11.1 Test conditions for four-ball friction and wear test

Test parameters

Applied load (kg) 40

Speed (rpm) 1200

Fuel temperature (°C) 35

Time (s) 3600

Ball dimensions

Material Chrome alloy steel

Composition C: (0.95–1.10)%, Cr: (1.3–1.6)%, Fe: balance

Diameter (mm) 12.7

Hardness (HRc) 62

Load

Rotating ball chuck

Rotating ball

Fuel sample

Stationary ball

Fig. 11.1 Schematic representation of four-ball tribotester.