Page 406 - Advances in Eco-Fuels for a Sustainable Environment

P. 406

360 Advances in Eco-Fuels for a Sustainable Environment

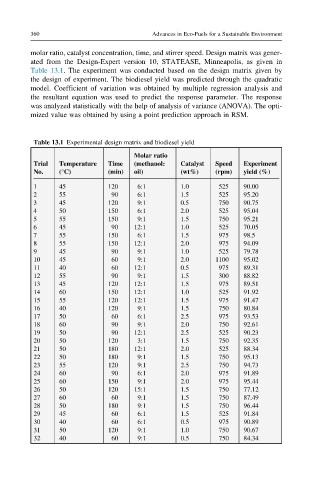

molar ratio, catalyst concentration, time, and stirrer speed. Design matrix was gener-

ated from the Design-Expert version 10, STATEASE, Minneapolis, as given in

Table 13.1. The experiment was conducted based on the design matrix given by

the design of experiment. The biodiesel yield was predicted through the quadratic

model. Coefficient of variation was obtained by multiple regression analysis and

the resultant equation was used to predict the response parameter. The response

was analyzed statistically with the help of analysis of variance (ANOVA). The opti-

mized value was obtained by using a point prediction approach in RSM.

Table 13.1 Experimental design matrix and biodiesel yield

Molar ratio

Trial Temperature Time (methanol: Catalyst Speed Experiment

No. (°C) (min) oil) (wt%) (rpm) yield (%)

1 45 120 6:1 1.0 525 90.00

2 55 90 6:1 1.5 525 95.20

3 45 120 9:1 0.5 750 90.75

4 50 150 6:1 2.0 525 95.04

5 55 150 9:1 1.5 750 95.21

6 45 90 12:1 1.0 525 70.05

7 55 150 6:1 1.5 975 98.5

8 55 150 12:1 2.0 975 94.09

9 45 90 9:1 1.0 525 79.78

10 45 60 9:1 2.0 1100 95.02

11 40 60 12:1 0.5 975 89.31

12 55 90 9:1 1.5 300 88.82

13 45 120 12:1 1.5 975 89.51

14 60 150 12:1 1.0 525 91.92

15 55 120 12:1 1.5 975 91.47

16 40 120 9:1 1.5 750 80.84

17 50 60 6:1 2.5 975 93.53

18 60 90 9:1 2.0 750 92.61

19 50 90 12:1 2.5 525 90.23

20 50 120 3:1 1.5 750 92.35

21 50 180 12:1 2.0 525 88.34

22 50 180 9:1 1.5 750 95.13

23 55 120 9:1 2.5 750 94.73

24 60 90 6:1 2.0 975 91.89

25 60 150 9:1 2.0 975 95.44

26 50 120 15:1 1.5 750 77.12

27 60 60 9:1 1.5 750 87.49

28 50 180 9:1 1.5 750 96.44

29 45 60 6:1 1.5 525 91.84

30 40 60 6:1 0.5 975 90.89

31 50 120 9:1 1.0 750 90.67

32 40 60 9:1 0.5 750 84.34