Page 458 - Advances in Eco-Fuels for a Sustainable Environment

P. 458

Eco friendly biofuels for CI engine applications 411

PSA gas

Water Sulphur Siloxanes

seperation seperation seperation seperation

Biogas system

40%–60% CH CO

4 2

Cooking Natural gas

compressor

Gas 95%–98% CH 4

Cylinders Vehicles

Industrial gas burners

Fig. 15.2 Schematic diagram of conversion of biogas to biomethane (CNG).

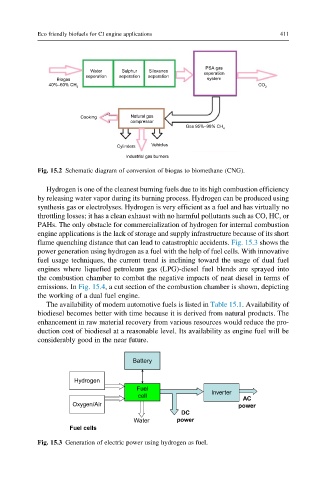

Hydrogen is one of the cleanest burning fuels due to its high combustion efficiency

by releasing water vapor during its burning process. Hydrogen can be produced using

synthesis gas or electrolyses. Hydrogen is very efficient as a fuel and has virtually no

throttling losses; it has a clean exhaust with no harmful pollutants such as CO, HC, or

PAHs. The only obstacle for commercialization of hydrogen for internal combustion

engine applications is the lack of storage and supply infrastructure because of its short

flame quenching distance that can lead to catastrophic accidents. Fig. 15.3 shows the

power generation using hydrogen as a fuel with the help of fuel cells. With innovative

fuel usage techniques, the current trend is inclining toward the usage of dual fuel

engines where liquefied petroleum gas (LPG)-diesel fuel blends are sprayed into

the combustion chamber to combat the negative impacts of neat diesel in terms of

emissions. In Fig. 15.4, a cut section of the combustion chamber is shown, depicting

the working of a dual fuel engine.

The availability of modern automotive fuels is listed in Table 15.1. Availability of

biodiesel becomes better with time because it is derived from natural products. The

enhancement in raw material recovery from various resources would reduce the pro-

duction cost of biodiesel at a reasonable level. Its availability as engine fuel will be

considerably good in the near future.

Battery

Hydrogen

Fuel

Inverter

cell

AC

Oxygen/Air power

DC

Water power

Fuel cells

Fig. 15.3 Generation of electric power using hydrogen as fuel.