Page 462 - Advances in Eco-Fuels for a Sustainable Environment

P. 462

Eco friendly biofuels for CI engine applications 415

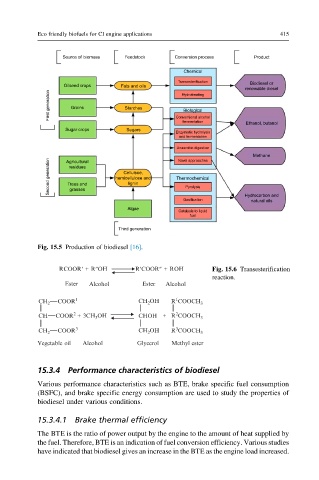

Source of biomass Feedstock Conversion process Product

Chemical

Transesterification Biodiesel or

Oilseed crops Fats and oils Hydrotreating renewable diesel

First generation Grains Starches Biological

Conventional alcohol

fermentation Ethanol, butanol

Sugar crops Sugars

Enzymatic hydrolysis

and fermentation

Anaerobic digestion

Methane

Second generation Trees and hemicellulose and Thermochemical

Novel approaches

Agricultural

residues

Cellulsoe,

lignin

Pyrolysis

grasses

Gasification Hydrocarbon and

natural oils

Algae

Catalysis to liquid

fuel

Third generation

Fig. 15.5 Production of biodiesel [16].

Fig. 15.6 Transesterification

RCOOR¢ + R²OH R¢COOR² + ROH

reaction.

Ester Alcohol Ester Alcohol

1 1

COOR CH OH R COOCH

2 3

CH 2

2 2

CH COOR + 3CH OH CHOH + R COOCH

3 3

3 3

CH COOR CH OH R COOCH

2 2 3

Vegetable oil Alcohol Glycerol Methyl ester

15.3.4 Performance characteristics of biodiesel

Various performance characteristics such as BTE, brake specific fuel consumption

(BSFC), and brake specific energy consumption are used to study the properties of

biodiesel under various conditions.

15.3.4.1 Brake thermal efficiency

The BTE is the ratio of power output by the engine to the amount of heat supplied by

the fuel. Therefore, BTE is an indication of fuel conversion efficiency. Various studies

have indicated that biodiesel gives an increase in the BTE as the engine load increased.