Page 261 - Air Pollution Control Engineering

P. 261

05_chap_wang.qxd 05/05/2004 3:46 pm Page 240

240 Lawrence K. Wang et al.

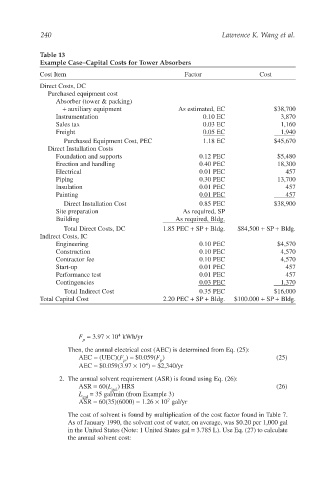

Table 13

Example Case–Capital Costs for Tower Absorbers

Cost Item Factor Cost

Direct Costs, DC

Purchased equipment cost

Absorber (tower & packing)

+ auxiliary equipment As estimated, EC $38,700

Instrumentation 0.10 EC 3,870

Sales tax 0.03 EC 1,160

Freight 0.05 EC 1,940

Purchased Equipment Cost, PEC 1.18 EC $45,670

Direct Installation Costs

Foundation and supports 0.12 PEC $5,480

Erection and handling 0.40 PEC 18,300

Electrical 0.01 PEC 457

Piping 0.30 PEC 13,700

Insulation 0.01 PEC 457

Painting 0.01 PEC 457

Direct Installation Cost 0.85 PEC $38,900

Site preparation As required, SP

Building As required, Bldg.

Total Direct Costs, DC 1.85 PEC + SP + Bldg. $84,500 + SP + Bldg.

Indirect Costs, IC

Engineering 0.10 PEC $4,570

Construction 0.10 PEC 4,570

Contractor fee 0.10 PEC 4,570

Start-up 0.01 PEC 457

Performance test 0.01 PEC 457

Contingencies 0.03 PEC 1,370

Total Indirect Cost 0.35 PEC $16,000

Total Capital Cost 2.20 PEC + SP + Bldg. $100.000 + SP + Bldg.

4

F = 3.97 × 10 kWh/yr

p

Then, the annual electrical cost (AEC) is determined from Eq. (25):

AEC = (UEC)(F ) = $0.059(F ) (25)

p p

4

AEC = $0.059(3.97 × 10 ) = $2,340/yr

2. The annual solvent requirement (ASR) is found using Eq. (26):

ASR = 60(L ) HRS (26)

gal

L = 35 gal/min (from Example 3)

gal

7

ASR = 60(35)(6000) = 1.26 × 10 gal/yr

The cost of solvent is found by multiplication of the cost factor found in Table 7.

As of January 1990, the solvent cost of water, on average, was $0.20 per 1,000 gal

in the United States (Note: 1 United States gal = 3.785 L). Use Eq. (27) to calculate

the annual solvent cost: