Page 304 - Air Pollution Control Engineering

P. 304

05_chap_wang.qxd 05/05/2004 3:51 pm Page 283

Wet and Dry Scrubbing 283

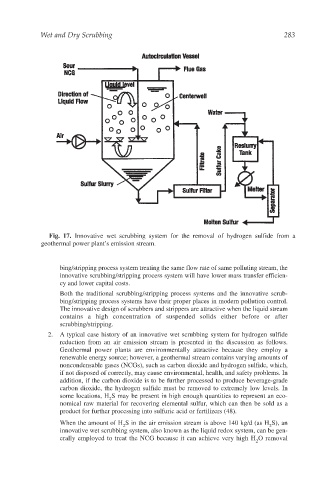

Fig. 17. Innovative wet scrubbing system for the removal of hydrogen sulfide from a

geothermal power plant’s emission stream.

bing/stripping process system treating the same flow rate of same polluting stream, the

innovative scrubbing/stripping process system will have lower mass transfer efficien-

cy and lower capital costs.

Both the traditional scrubbing/stripping process systems and the innovative scrub-

bing/stripping process systems have their proper places in modern pollution control.

The innovative design of scrubbers and strippers are attractive when the liquid stream

contains a high concentration of suspended solids either before or after

scrubbing/stripping.

2. A typical case history of an innovative wet scrubbing system for hydrogen sulfide

reduction from an air emission stream is presented in the discussion as follows.

Geothermal power plants are environmentally attractive because they employ a

renewable energy source; however, a geothermal stream contains varying amounts of

noncondensable gases (NCGs), such as carbon dioxide and hydrogen sulfide, which,

if not disposed of correctly, may cause environmental, health, and safety problems. In

addition, if the carbon dioxide is to be further processed to produce beverage-grade

carbon dioxide, the hydrogen sulfide must be removed to extremely low levels. In

some locations, H S may be present in high enough quantities to represent an eco-

2

nomical raw material for recovering elemental sulfur, which can then be sold as a

product for further processing into sulfuric acid or fertilizers (48).

When the amount of H S in the air emission stream is above 140 kg/d (as H S), an

2 2

innovative wet scrubbing system, also known as the liquid redox system, can be gen-

erally employed to treat the NCG because it can achieve very high H O removal

2