Page 288 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 288

9.3 SO 2 Capture by Furnace Sorbent Injection 265

Sorbent injection Humidification Clean air

Particulate

Air control devices

heater

CaCO 3 or Boiler

Ca(OH) 2

Stack

Disposal

Reactivation

Product

Optional Recycle

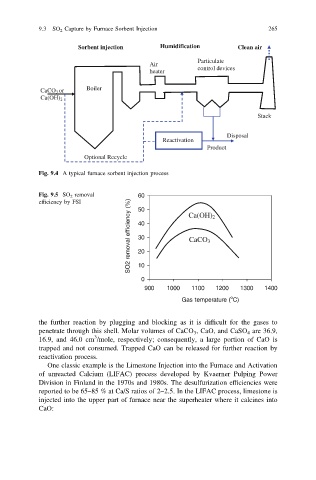

Fig. 9.4 A typical furnace sorbent injection process

Fig. 9.5 SO 2 removal 60

SO2 removal efficiency (%) 40 CaCO 3

efficiency by FSI 50 Ca(OH) 2

30

20

10

0

900 1000 1100 1200 1300 1400

o

Gas temperature ( C)

the further reaction by plugging and blocking as it is difficult for the gases to

penetrate through this shell. Molar volumes of CaCO 3 , CaO, and CaSO 4 are 36.9,

3

16.9, and 46.0 cm /mole, respectively; consequently, a large portion of CaO is

trapped and not consumed. Trapped CaO can be released for further reaction by

reactivation process.

One classic example is the Limestone Injection into the Furnace and Activation

of unreacted Calcium (LIFAC) process developed by Kvaerner Pulping Power

Division in Finland in the 1970s and 1980s. The desulfurization efficiencies were

reported to be 65–85 % at Ca/S ratios of 2–2.5. In the LIFAC process, limestone is

injected into the upper part of furnace near the superheater where it calcines into

CaO: