Page 392 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 392

12.6 CO 2 Separation by Absorption 371

0

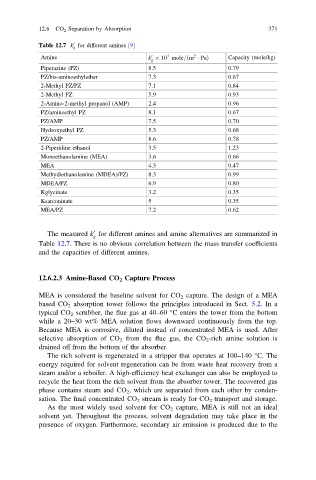

Table 12.7 k for different amines [9]

g

7

Amine k 10 mole= m Pað 2 Þ Capacity (mole/kg)

0

g

Piperazine (PZ) 8.5 0.79

PZ/bis-aminoethylether 7.3 0.67

2-Methyl PZ/PZ 7.1 0.84

2-Methyl PZ 5.9 0.93

2-Amino-2-methyl propanol (AMP) 2.4 0.96

PZ/aminoethyl PZ 8.1 0.67

PZ/AMP 7.5 0.70

Hydroxyethyl PZ 5.3 0.68

PZ/AMP 8.6 0.78

2-Piperidine ethanol 3.5 1.23

Monoethanolamine (MEA) 3.6 0.66

MEA 4.3 0.47

Methydiethanolamine (MDEA)/PZ) 8.3 0.99

MDEA/PZ 6.9 0.80

Kglycinate 3.2 0.35

Ksarconinate 5 0.35

MEA/PZ 7.2 0.62

0

The measured k for different amines and amine alternatives are summarized in

g

Table 12.7. There is no obvious correlation between the mass transfer coefficients

and the capacities of different amines.

12.6.2.3 Amine-Based CO 2 Capture Process

MEA is considered the baseline solvent for CO 2 capture. The design of a MEA

based CO 2 absorption tower follows the principles introduced in Sect. 5.2.Ina

typical CO 2 scrubber, the flue gas at 40–60 °C enters the tower from the bottom

while a 20–30 wt% MEA solution flows downward continuously from the top.

Because MEA is corrosive, diluted instead of concentrated MEA is used. After

selective absorption of CO 2 from the flue gas, the CO 2 -rich amine solution is

drained off from the bottom of the absorber.

The rich solvent is regenerated in a stripper that operates at 100–140 °C. The

energy required for solvent regeneration can be from waste heat recovery from a

steam and/or a reboiler. A high-efficiency heat exchanger can also be employed to

recycle the heat from the rich solvent from the absorber tower. The recovered gas

phase contains steam and CO 2 , which are separated from each other by conden-

sation. The final concentrated CO 2 stream is ready for CO 2 transport and storage.

As the most widely used solvent for CO 2 capture, MEA is still not an ideal

solvent yet. Throughout the process, solvent degradation may take place in the

presence of oxygen. Furthermore, secondary air emission is produced due to the