Page 28 - Air and Gas Drilling Manual

P. 28

Chapter 1: Introduction 1-5

Single rigs can be fitted with either an on-board air compressor, or an on-board

mud pump. Some of these rigs can accommodate both subsystems. These rigs have

either a dedicated prime mover on the rig deck, or have a power-take-off system

which allows utilization of the truck motor as a prime mover for the drilling rig

equipment (when the truck is stationary). These small drilling rigs provide axial

force to the drill bit through the drill string via a chain or cable actuated pull-down

system, or hydraulic pull-down system. A pull-down system transfers a portion of

the weight of the rig to the top of the drill string and then to the drill bit. The

torque and rotation at the top of the drill string is provided by a hydraulic tophead

drive (similar to power swivel systems used on larger drilling rigs) which is moved

up and down the mast (on a track) by the chain drive pull-down system. Many of

these small single drilling rigs are capable of drilling with their masts at a 45˚ angle

to the vertical. The prime mover for these rigs is usually diesel fueled.

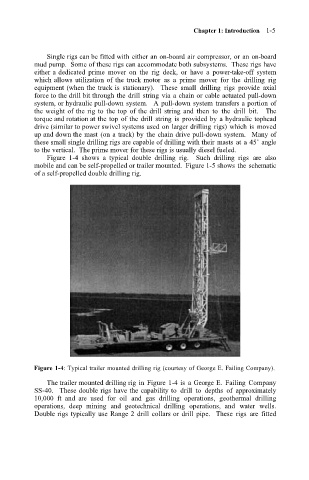

Figure 1-4 shows a typical double drilling rig. Such drilling rigs are also

mobile and can be self-propelled or trailer mounted. Figure 1-5 shows the schematic

of a self-propelled double drilling rig.

Figure 1-4: Typical trailer mounted drilling rig (courtesy of George E. Failing Company).

The trailer mounted drilling rig in Figure 1-4 is a George E. Failing Company

SS-40. These double rigs have the capability to drill to depths of approximately

10,000 ft and are used for oil and gas drilling operations, geothermal drilling

operations, deep mining and geotechnical drilling operations, and water wells.

Double rigs typically use Range 2 drill collars or drill pipe. These rigs are fitted