Page 32 - Air and Gas Drilling Manual

P. 32

Chapter 1: Introduction 1-9

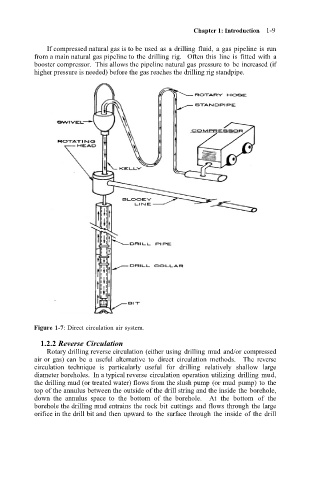

If compressed natural gas is to be used as a drilling fluid, a gas pipeline is run

from a main natural gas pipeline to the drilling rig. Often this line is fitted with a

booster compressor. This allows the pipeline natural gas pressure to be increased (if

higher pressure is needed) before the gas reaches the drilling rig standpipe.

Figure 1-7: Direct circulation air system.

1.2.2 Reverse Circulation

Rotary drilling reverse circulation (either using drilling mud and/or compressed

air or gas) can be a useful alternative to direct circulation methods. The reverse

circulation technique is particularly useful for drilling relatively shallow large

diameter boreholes. In a typical reverse circulation operation utilizing drilling mud,

the drilling mud (or treated water) flows from the slush pump (or mud pump) to the

top of the annulus between the outside of the drill string and the inside the borehole,

down the annulus space to the bottom of the borehole. At the bottom of the

borehole the drilling mud entrains the rock bit cuttings and flows through the large

orifice in the drill bit and then upward to the surface through the inside of the drill