Page 34 - Air and Gas Drilling Manual

P. 34

Chapter 1: Introduction 1-11

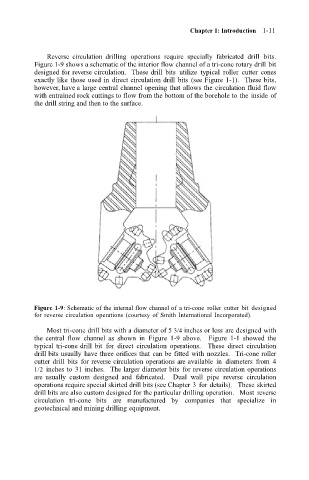

Reverse circulation drilling operations require specially fabricated drill bits.

Figure 1-9 shows a schematic of the interior flow channel of a tri-cone rotary drill bit

designed for reverse circulation. These drill bits utilize typical roller cutter cones

exactly like those used in direct circulation drill bits (see Figure 1-1). These bits,

however, have a large central channel opening that allows the circulation fluid flow

with entrained rock cuttings to flow from the bottom of the borehole to the inside of

the drill string and then to the surface.

Figure 1-9: Schematic of the internal flow channel of a tri-cone roller cutter bit designed

for reverse circulation operations (courtesy of Smith International Incorporated).

Most tri-cone drill bits with a diameter of 5 3/4 inches or less are designed with

the central flow channel as shown in Figure 1-9 above. Figure 1-1 showed the

typical tri-cone drill bit for direct circulation operations. These direct circulation

drill bits usually have three orifices that can be fitted with nozzles. Tri-cone roller

cutter drill bits for reverse circulation operations are available in diameters from 4

1/2 inches to 31 inches. The larger diameter bits for reverse circulation operations

are usually custom designed and fabricated. Dual wall pipe reverse circulation

operations require special skirted drill bits (see Chapter 3 for details). These skirted

drill bits are also custom designed for the particular drilling operation. Most reverse

circulation tri-cone bits are manufactured by companies that specialize in

geotechnical and mining drilling equipment.