Page 570 - Air and Gas Drilling Manual

P. 570

11-8 Air and Gas Drilling Manual

11.1.3 Snubbing Units

In oil and natural gas recovery drilling, there are special operational situations

that require the insertion of a drill string or a liner into a well that has been shut-in

and is under high internal gas pressure. These situations are usually either the result

of an unexpected subsurface blowout, or due to the operational desire to complete a

well without damaging the natural gas production zone (i.e., underbalanced drilling

and completion). Inserting tubulars into a shut-in high pressure well is a potentially

dangerous operation and requires unique surface equipment to accomplish. If

sufficient gas is released from the well to the atmosphere to compensate for the

tubulars volume, then the insertion operation is known as a snubbing operation. If,

on the other hand, the well is allowed to flow through the blooey line to the

atmosphere as the tubulars are inserted, the operation is known as a stripping

operation. Stripping operations are usually designed for low wellhead pressures and,

thus, do not require snubbing units. Inserting a tubular against the static pressure of

a well requires the assistance of the snubbing unit to force the tubular into the well.

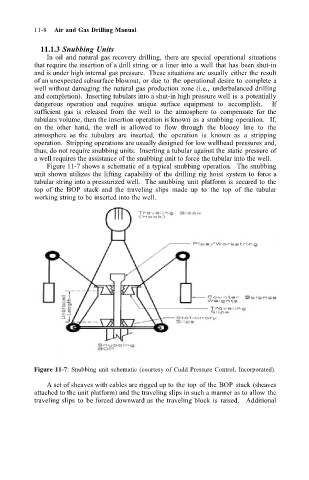

Figure 11-7 shows a schematic of a typical snubbing operation. The snubbing

unit shown utilizes the lifting capability of the drilling rig hoist system to force a

tubular string into a pressurized well. The snubbing unit platform is secured to the

top of the BOP stack and the traveling slips made up to the top of the tubular

working string to be inserted into the well.

Figure 11-7: Snubbing unit schematic (courtesy of Cudd Pressure Control, Incorporated).

A set of sheaves with cables are rigged up to the top of the BOP stack (sheaves

attached to the unit platform) and the traveling slips in such a manner as to allow the

traveling slips to be forced downward as the traveling block is raised. Additional