Page 572 - Air and Gas Drilling Manual

P. 572

11-10 Air and Gas Drilling Manual

11.2 Downhole Equipment

There are several downhole drilling devices that are unique to air and gas

drilling operations. These are the downhole air hammer, the progressive cavity

positive displacement motor (modified for compressed gas drilling fluids), the

downhole pneumatic turbine motor, and the sliding vane positive displacement

motor.

11.2.1 Downhole Air Hammers

There are two basic designs for the downhole air hammer. One design utilizes a

flow path of the compressed air through a control rod (or feed tube) down the center

hammer piston (or through passages in the piston) and then through the hammer bit.

The other design utilizes a flow path through a housing annulus passage (around the

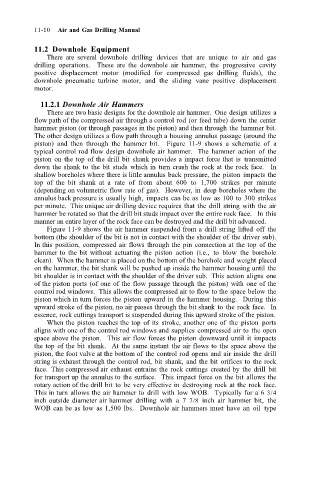

piston) and then through the hammer bit. Figure 11-9 shows a schematic of a

typical control rod flow design downhole air hammer. The hammer action of the

piston on the top of the drill bit shank provides a impact force that is transmitted

down the shank to the bit studs which in turn crush the rock at the rock face. In

shallow boreholes where there is little annulus back pressure, the piston impacts the

top of the bit shank at a rate of from about 600 to 1,700 strikes per minute

(depending on volumetric flow rate of gas). However, in deep boreholes where the

annulus back pressure is usually high, impacts can be as low as 100 to 300 strikes

per minute. This unique air drilling device requires that the drill string with the air

hammer be rotated so that the drill bit studs impact over the entire rock face. In this

manner an entire layer of the rock face can be destroyed and the drill bit advanced.

Figure 11-9 shows the air hammer suspended from a drill string lifted off the

bottom (the shoulder of the bit is not in contact with the shoulder of the driver sub).

In this position, compressed air flows through the pin connection at the top of the

hammer to the bit without actuating the piston action (i.e., to blow the borehole

clean). When the hammer is placed on the bottom of the borehole and weight placed

on the hammer, the bit shank will be pushed up inside the hammer housing until the

bit shoulder is in contact with the shoulder of the driver sub. This action aligns one

of the piston ports (of one of the flow passage through the piston) with one of the

control rod windows. This allows the compressed air to flow to the space below the

piston which in turn forces the piston upward in the hammer housing. During this

upward stroke of the piston, no air passes through the bit shank to the rock face. In

essence, rock cuttings transport is suspended during this upward stroke of the piston.

When the piston reaches the top of its stroke, another one of the piston ports

aligns with one of the control rod windows and supplies compressed air to the open

space above the piston. This air flow forces the piston downward until it impacts

the top of the bit shank. At the same instant the air flows to the space above the

piston, the foot valve at the bottom of the control rod opens and air inside the drill

string is exhaust through the control rod, bit shank, and the bit orifices to the rock

face. This compressed air exhaust entrains the rock cuttings created by the drill bit

for transport up the annulus to the surface. This impact force on the bit allows the

rotary action of the drill bit to be very effective in destroying rock at the rock face.

This in turn allows the air hammer to drill with low WOB. Typically for a 6 3/4

inch outside diameter air hammer drilling with a 7 7/8 inch air hammer bit, the

WOB can be as low as 1,500 lbs. Downhole air hammers must have an oil type