Page 175 - Air and gas Drilling Field Guide 3rd Edition

P. 175

166 CHAPTER 7 Reverse Circulation Models

P e

P in (All)

P

P bca

d P

H

P bdpa P bdpi

P bdci

P ai

P bdca =P bh

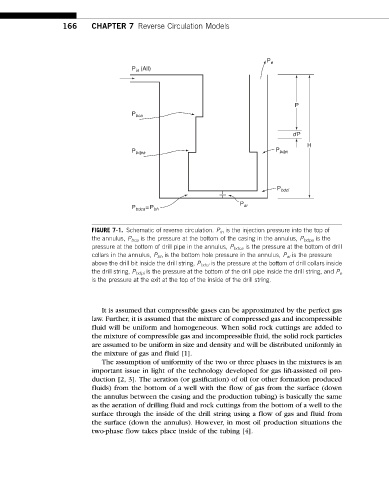

FIGURE 7-1. Schematic of reverse circulation. P in is the injection pressure into the top of

the annulus, P bca is the pressure at the bottom of the casing in the annulus, P bdpa is the

pressure at the bottom of drill pipe in the annulus, P bdca is the pressure at the bottom of drill

collars in the annulus, P bh is the bottom hole pressure in the annulus, P ai is the pressure

above the drill bit inside the drill string, P bdci is the pressure at the bottom of drill collars inside

the drill string, P bdpi is the pressure at the bottom of the drill pipe inside the drill string, and P e

is the pressure at the exit at the top of the inside of the drill string.

It is assumed that compressible gases can be approximated by the perfect gas

law. Further, it is assumed that the mixture of compressed gas and incompressible

fluid will be uniform and homogeneous. When solid rock cuttings are added to

the mixture of compressible gas and incompressible fluid, the solid rock particles

are assumed to be uniform in size and density and will be distributed uniformly in

the mixture of gas and fluid [1].

The assumption of uniformity of the two or three phases in the mixtures is an

important issue in light of the technology developed for gas lift-assisted oil pro-

duction [2, 3]. The aeration (or gasification) of oil (or other formation produced

fluids) from the bottom of a well with the flow of gas from the surface (down

the annulus between the casing and the production tubing) is basically the same

as the aeration of drilling fluid and rock cuttings from the bottom of a well to the

surface through the inside of the drill string using a flow of gas and fluid from

the surface (down the annulus). However, in most oil production situations the

two-phase flow takes place inside of the tubing [4].