Page 225 - Air and gas Drilling Field Guide 3rd Edition

P. 225

216 CHAPTER 9 Aerated Fluids Drilling

P (All)

in

P e

P bca

P bdpi

P bdpa

P bdci

P ai

P bdca =P bh

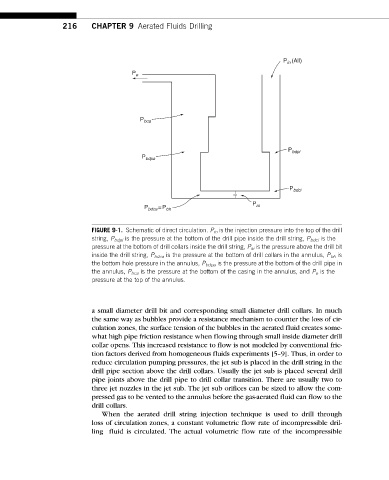

FIGURE 9-1. Schematic of direct circulation. P in is the injection pressure into the top of the drill

string, P bdpi is the pressure at the bottom of the drill pipe inside the drill string, P bdci is the

pressure at the bottom of drill collars inside the drill string, P ai is the pressure above the drill bit

inside the drill string, P bdca is the pressure at the bottom of drill collars in the annulus, P bh is

the bottom hole pressure in the annulus, P bdpa is the pressure at the bottom of the drill pipe in

the annulus, P bca is the pressure at the bottom of the casing in the annulus, and P e is the

pressure at the top of the annulus.

a small diameter drill bit and corresponding small diameter drill collars. In much

the same way as bubbles provide a resistance mechanism to counter the loss of cir-

culation zones, the surface tension of the bubbles in the aerated fluid creates some-

what high pipe friction resistance when flowing through small inside diameter drill

collar opens. This increased resistance to flow is not modeled by conventional fric-

tion factors derived from homogeneous fluids experiments [5–9]. Thus, in order to

reduce circulation pumping pressures, the jet sub is placed in the drill string in the

drill pipe section above the drill collars. Usually the jet sub is placed several drill

pipe joints above the drill pipe to drill collar transition. There are usually two to

three jet nozzles in the jet sub. The jet sub orifices can be sized to allow the com-

pressed gas to be vented to the annulus before the gas-aerated fluid can flow to the

drill collars.

When the aerated drill string injection technique is used to drill through

loss of circulation zones, a constant volumetric flow rate of incompressible dril-

ling fluid is circulated. The actual volumetric flow rate of the incompressible