Page 227 - Air and gas Drilling Field Guide 3rd Edition

P. 227

218 CHAPTER 9 Aerated Fluids Drilling

P in (Gas)

P (Liquid)

in

P e

P bca

P bdpi

P bdpa

P bdci

P ai

P bdca =P bh

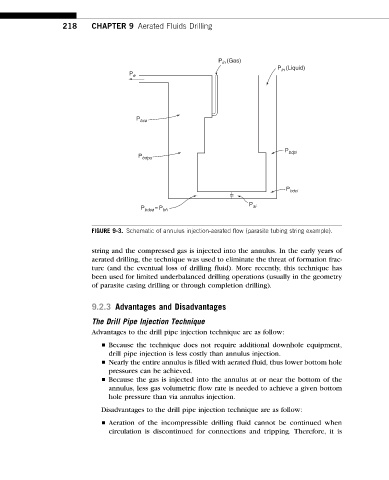

FIGURE 9-3. Schematic of annulus injection-aerated flow (parasite tubing string example).

string and the compressed gas is injected into the annulus. In the early years of

aerated drilling, the technique was used to eliminate the threat of formation frac-

ture (and the eventual loss of drilling fluid). More recently, this technique has

been used for limited underbalanced drilling operations (usually in the geometry

of parasite casing drilling or through completion drilling).

9.2.3 Advantages and Disadvantages

The Drill Pipe Injection Technique

Advantages to the drill pipe injection technique are as follow:

n Because the technique does not require additional downhole equipment,

drill pipe injection is less costly than annulus injection.

n Nearly the entire annulus is filled with aerated fluid, thus lower bottom hole

pressures can be achieved.

n Because the gas is injected into the annulus at or near the bottom of the

annulus, less gas volumetric flow rate is needed to achieve a given bottom

hole pressure than via annulus injection.

Disadvantages to the drill pipe injection technique are as follow:

n Aeration of the incompressible drilling fluid cannot be continued when

circulation is discontinued for connections and tripping. Therefore, it is