Page 287 - Aircraft Stuctures for Engineering Student

P. 287

268 Airworthiness and airframe loads

@ @ front

Crack

Crack

front

front

1 Tension, normal Shear, normal Shear, parallel to

to crack front

to faces of crack

crack front

in plane of crack

(opening mode)

(tearing mode)

(edge sliding mode)

(a) ( b) (C)

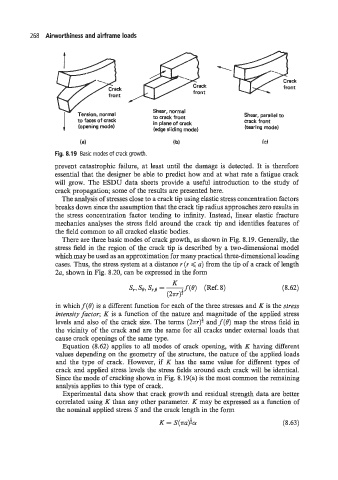

Fig. 8.19 Basic modes of crack growth.

prevent catastrophic failure, at least until the damage is detected. It is therefore

essential that the designer be able to predict how and at what rate a fatigue crack

will grow. The ESDU data sheets provide a useful introduction to the study of

crack propagation; some of the results are presented here.

The analysis of stresses close to a crack tip using elastic stress concentration factors

breaks down since the assumption that the crack tip radius approaches zero results in

the stress concentration factor tending to infinity. Instead, linear elastic fracture

mechanics analyses the stress field around the crack tip and identifies features of

the field common to all cracked elastic bodies.

There are three basic modes of crack growth, as shown in Fig. 8.19. Generally, the

stress field in the region of the crack tip is described by a two-dimensional model

which may be used as an approximation for many practical three-dimensional loading

cases. Thus, the stress system at a distance I (I < u) from the tip of a crack of length

24 shown in Fig. 8.20, can be expressed in the form

(8.62)

in whichf(8) is a different function for each of the three stresses and K is the stress

intensity factor; K is a function of the nature and magnitude of the applied stress

levels and also of the crack size. The terms (2xr)f andf(8) map the stress field in

the vicinity of the crack and are the same for all cracks under external loads that

cause crack openings of the same type.

Equation (8.62) applies to all modes of crack opening, with K having different

values depending on the geometry of the structure, the nature of the applied loads

and the type of crack. However, if K has the same value for different types of

crack and applied stress levels the stress fields around each crack will be identical.

Since the mode of cracking shown in Fig. 8.19(a) is the most common the remaining

analysis applies to this type of crack.

Experimental data show that crack growth and residual strength data are better

correlated using K than any other parameter. K may be expressed as a function of

the nominal applied stress S and the crack length in the form

K = S(.rru)fa (8.63)