Page 56 - Alternative Energy Systems in Building Design

P. 56

SOLAR CELL MANUFACTURING AND PACKAGING TECHNOLOGIES 33

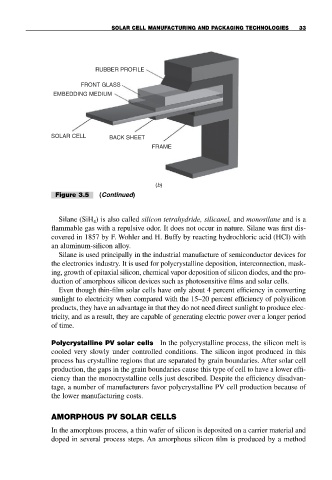

RUBBER PROFILE

FRONT GLASS

EMBEDDING MEDIUM

SOLAR CELL BACK SHEET

FRAME

(b)

Figure 3.5 (Continued)

Silane (SiH ) is also called silicon tetrahydride, silicanel, and monosilane and is a

4

flammable gas with a repulsive odor. It does not occur in nature. Silane was first dis-

covered in 1857 by F. Wohler and H. Buffy by reacting hydrochloric acid (HCl) with

an aluminum-silicon alloy.

Silane is used principally in the industrial manufacture of semiconductor devices for

the electronics industry. It is used for polycrystalline deposition, interconnection, mask-

ing, growth of epitaxial silicon, chemical vapor deposition of silicon diodes, and the pro-

duction of amorphous silicon devices such as photosensitive films and solar cells.

Even though thin-film solar cells have only about 4 percent efficiency in converting

sunlight to electricity when compared with the 15–20 percent efficiency of polysilicon

products, they have an advantage in that they do not need direct sunlight to produce elec-

tricity, and as a result, they are capable of generating electric power over a longer period

of time.

Polycrystalline PV solar cells In the polycrystalline process, the silicon melt is

cooled very slowly under controlled conditions. The silicon ingot produced in this

process has crystalline regions that are separated by grain boundaries. After solar cell

production, the gaps in the grain boundaries cause this type of cell to have a lower effi-

ciency than the monocrystalline cells just described. Despite the efficiency disadvan-

tage, a number of manufacturers favor polycrystalline PV cell production because of

the lower manufacturing costs.

AMORPHOUS PV SOLAR CELLS

In the amorphous process, a thin wafer of silicon is deposited on a carrier material and

doped in several process steps. An amorphous silicon film is produced by a method