Page 127 -

P. 127

MORE THAN TWO DECISION VARIABLES 107

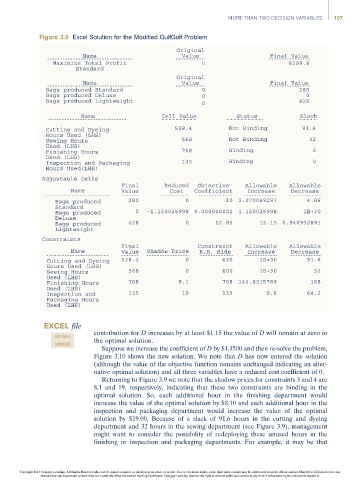

Figure 3.9 Excel Solution for the Modified GulfGolf Problem

Original

Name Value Final Value

Maximize Total Profit 0 8299.8

Standard

Original

Name Value Final Value

Bags produced Standard 0 280

Bags produced Deluxe 0 0

Bags produced Lightweight 0 428

Name Cell Value Status Slack

Cutting and Dyeing 538.4 Not Binding 91.6

Hours Used (LHS)

Sewing Hours 568 Not Binding 32

Used (LHS)

Finishing Hours 708 Binding 0

Used (LHS)

Inspection and Packaging 135 Binding 0

Hours Used(LHS)

Adjustable Cells

Final Reduced Objective Allowable Allowable

Name Value Cost Coefficient Increase Decrease

Bags produced 280 0 10 2.070069297 4.86

Standard

Bags produced 0 –1.150026998 9.000000002 1.150026998 1E+30

Deluxe

Bags produced 428 0 12.85 12.15 0.940932891

Lightweight

Constraints

Final Constraint Allowable Allowable

Name Value Shadow Price R.H. Side Increase Decrease

Cutting and Dyeing 538.4 0 630 1E+30 91.6

Hours Used (LHS)

Sewing Hours 568 0 600 1E+30 32

Used (LHS)

Finishing Hours 708 8.1 708 144.6315789 168

Used (LHS)

Inspection and 135 19 135 9.6 64.2

Packaging Hours

Used (LHS)

EXCEL file

contribution for D increases by at least $1.15 the value of D will remain at zero in

GULFGOLF

the optimal solution.

MODIFIED

Suppose we increase the coefficient of D by $1.1500 and then re-solve the problem.

Figure 3.10 shows the new solution. We note that D has now entered the solution

(although the value of the objective function remains unchanged indicating an alter-

native optimal solution) and all three variables have a reduced cost coefficient of 0.

Returning to Figure 3.9 we note that the shadow prices for constraints 3 and 4 are

8.1 and 19, respectively, indicating that these two constraints are binding in the

optimal solution. So, each additional hour in the finishing department would

increase the value of the optimal solution by $8.10 and each additional hour in the

inspection and packaging department would increase the value of the optimal

solution by $19.00. Because of a slack of 91.6 hours in the cutting and dyeing

department and 32 hours in the sewing department (see Figure 3.9), management

might want to consider the possibility of redeploying these unused hours in the

finishing or inspection and packaging departments. For example, it may be that

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.