Page 217 -

P. 217

DATA ENVELOPMENT ANALYSIS 197

maintenance and driver availability, the firm does not want to add more than 15 new

vehicles to its fleet. In addition, the company has decided to purchase at least three of the

new Econo-Tankers for use on short-run, low-demand routes. As a final constraint, the

company does not want more than half the new models to be Super Tankers.

a. If the company wishes to satisfy the gasoline demand with a minimum monthly

operating expense, how many models of each truck should be purchased?

b. If the company did not require at least three Econo-Tankers and did not limit the number

of Super Tankers to at most half the new models, how many models of each truck

should be purchased?

14 TheSilverStarBicycle CompanyinIndia will be manufacturingbothmen’s andwomen’s

models for its Easy-Pedal ten-speed bicycles during the next two months. Management wants

to develop a production schedule indicating how many bicycles of each model should be

produced in each month. Current demand forecasts call for 150 men’s and 125 women’s

models to be shipped during the first month and 200 men’s and 150 women’s models to be

shipped during the second month. Additional data are shown.

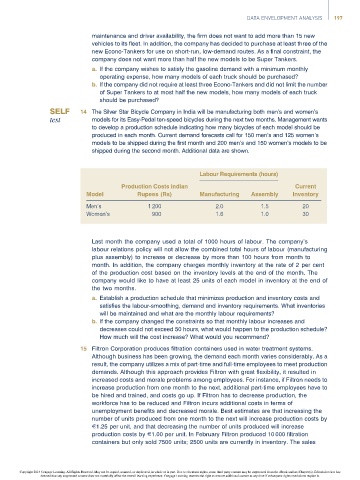

Labour Requirements (hours)

Production Costs Indian Current

Model Rupees (Rs) Manufacturing Assembly Inventory

Men’s 1 200 2.0 1.5 20

Women’s 900 1.6 1.0 30

Last month the company used a total of 1000 hours of labour. The company’s

labour relations policy will not allow the combined total hours of labour (manufacturing

plus assembly)toincreaseordecreasebymorethan 100hoursfrommonth to

month. In addition, the company charges monthly inventory at the rate of 2 per cent

of the production cost based on the inventory levels at the end of the month. The

company would like to have at least 25 units of each model in inventory at the end of

the two months.

a. Establish a production schedule that minimizes production and inventory costs and

satisfies the labour-smoothing, demand and inventory requirements. What inventories

will be maintained and what are the monthly labour requirements?

b. If the company changed the constraints so that monthly labour increases and

decreases could not exceed 50 hours, what would happen to the production schedule?

How much will the cost increase? What would you recommend?

15 Filtron Corporation produces filtration containers used in water treatment systems.

Although business has been growing, the demand each month varies considerably. As a

result, the company utilizes a mix of part-time and full-time employees to meet production

demands. Although this approach provides Filtron with great flexibility, it resulted in

increased costs and morale problems among employees. For instance, if Filtron needs to

increase production from one month to the next, additional part-time employees have to

be hired and trained, and costs go up. If Filtron has to decrease production, the

workforce has to be reduced and Filtron incurs additional costs in terms of

unemployment benefits and decreased morale. Best estimates are that increasing the

number of units produced from one month to the next will increase production costs by

E1.25 per unit, and that decreasing the number of units produced will increase

production costs by E1.00 per unit. In February Filtron produced 10 000 filtration

containers but only sold 7500 units; 2500 units are currently in inventory. The sales

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.