Page 218 -

P. 218

198 CHAPTER 4 LINEAR PROGRAMMING APPLICATIONS

forecasts for March, April and May are for 12 000 units, 8 000 units and 15 000 units,

respectively. In addition, Filtron has the capacity to store up to 3000 filtration containers

at the end of any month. Management would like to determine the number of units to be

produced in March, April and May that will minimize the total cost of the monthly

production increases and decreases.

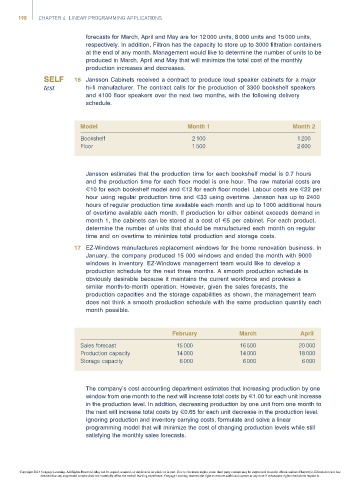

16 Jansson Cabinets received a contract to produce loud speaker cabinets for a major

hi-fi manufacturer. The contract calls for the production of 3300 bookshelf speakers

and 4100 floor speakers over the next two months, with the following delivery

schedule.

Model Month 1 Month 2

Bookshelf 2 100 1 200

Floor 1 500 2 600

Jansson estimates that the production time for each bookshelf model is 0.7 hours

and the production time for each floor model is one hour. The raw material costs are

E10 for each bookshelf model and E12 for each floor model. Labour costs are E22 per

hour using regular production time and E33 using overtime. Jansson has up to 2400

hours of regular production time available each month and up to 1000 additional hours

of overtime available each month. If production for either cabinet exceeds demand in

month 1, the cabinets can be stored at a cost of E5 per cabinet. For each product,

determine the number of units that should be manufactured each month on regular

time and on overtime to minimize total production and storage costs.

17 EZ-Windows manufactures replacement windows for the home renovation business. In

January, the company produced 15 000 windows and ended the month with 9000

windows in inventory. EZ-Windows management team would like to develop a

production schedule for the next three months. A smooth production schedule is

obviously desirable because it maintains the current workforce and provides a

similar month-to-month operation. However, given the sales forecasts, the

production capacities and the storage capabilities as shown, the management team

does not think a smooth production schedule with the same production quantity each

month possible.

February March April

Sales forecast 15 000 16 500 20 000

Production capacity 14 000 14 000 18 000

Storage capacity 6 000 6 000 6 000

The company’s cost accounting department estimates that increasing production by one

window from one month to the next will increase total costs by E1.00 for each unit increase

in the production level. In addition, decreasing production by one unit from one month to

the next will increase total costs by E0.65 for each unit decrease in the production level.

Ignoring production and inventory carrying costs, formulate and solve a linear

programming model that will minimize the cost of changing production levels while still

satisfying the monthly sales forecasts.

Copyright 2014 Cengage Learning. All Rights Reserved. May not be copied, scanned, or duplicated, in whole or in part. Due to electronic rights, some third party content may be suppressed from the eBook and/or eChapter(s). Editorial review has

deemed that any suppressed content does not materially affect the overall learning experience. Cengage Learning reserves the right to remove additional content at any time if subsequent rights restrictions require it.