Page 196 - An Introduction to Microelectromechanical Systems Engineering

P. 196

DNA Analysis 175

conduction, and volume determines the amount of heat necessary for a thermal

cycle. A greater ratio of surface area to volume, therefore, enables faster thermal

cycling in PCR. Because the chamber volume is smaller, less sample and volume of

expensive reagents is needed. If integrated with a detection scheme such as electro-

phoretic separation or TaqMan tagging (described later) on the same chip, the

entire process is simplified, making it faster, less expensive, and more repeatable.

PCR on a silicon chip was first demonstrated around 1994 by several groups

[10, 11], and by the end of the 1990s there had been several demonstrations of PCR

on a chip. This section describes silicon miniature PCR thermal cycling chambers

developed at Lawrence Livermore National Laboratory (LLNL) of Livermore, Cali-

fornia (see Figure 6.4) [12]. Different versions of this chamber are at the core of

portable analytical instruments under development at Cepheid of Sunnyvale, Cali-

fornia, and Microfluidic Systems, Inc., of Pleasanton, California.

Several generations of micromachined chambers have been fabricated at LLNL

[13]. They thermally cycle a solution between the denaturing and incubation tem-

peratures, approximately 95ºC and 60ºC, respectively. One chamber, with a vol-

ume of 25 to 100 µl, is made of two silicon chips with etched grooves, which are

bonded together. A silicon nitride window provides optical access. Experimental

results have shown that bare silicon inhibits PCR amplification, so a disposable

polypropylene liner was added to the chamber. This slows the rate at which the

chamber can be heated and cooled slightly from an all-silicon version to about

8°C/s. An advantage of a disposable liner is that the chamber no longer has to be

cleaned. Eliminating this time-consuming operation enables more samples to be run

per day.

Earlier designs had a polysilicon heater on a silicon nitride membrane for heat-

ing the fluid inside the chamber and used a separate, external temperature sensor.

By changing the heater material to platinum, which is commonly used as a tempera-

ture sensor, both heating and sensing operations can be performed with the same

platinum element. Testing of early devices showed that there were temperature

variations as high as 10°C across the chamber. By relocating the heater away from

Glass Polysilicon heater

Bondpad

Silicon nitride

membrane

Polyethylene

~10mm tubing

Silicone

sealant

Glass

(a) (b)

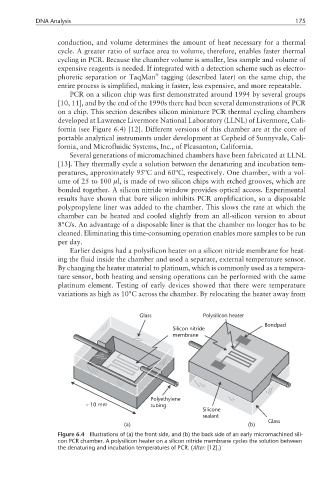

Figure 6.4 Illustrations of (a) the front side, and (b) the back side of an early micromachined sili-

con PCR chamber. A polysilicon heater on a silicon nitride membrane cycles the solution between

the denaturing and incubation temperatures of PCR. (After: [12].)